Products

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

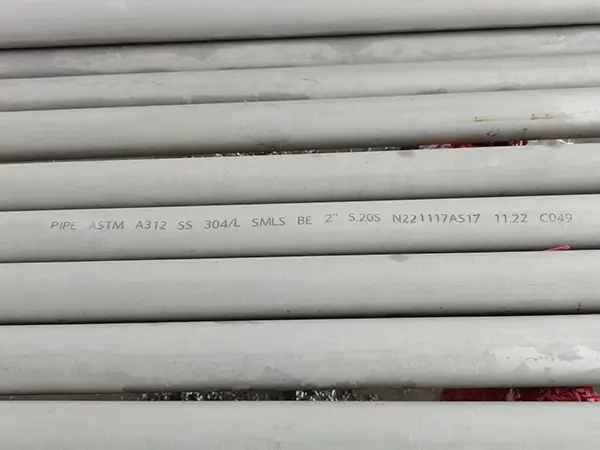

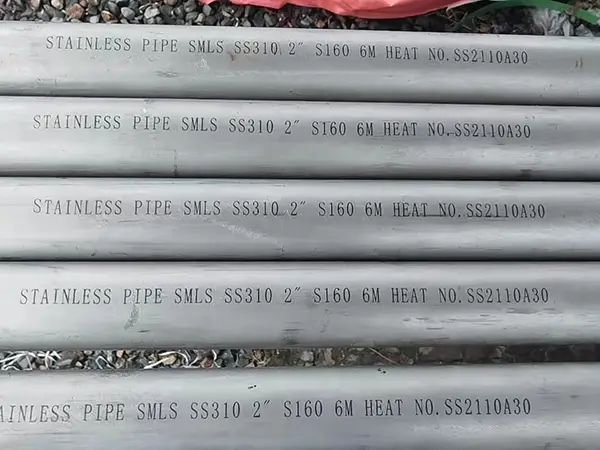

Centerway steel Stainless Products stocks stainless steel Seamless pipe per ASTM A 312 in 304/304L and 316/316L. We supply other stainless grades, including 304H, 316H, 309/S, 310/S, 317/L, 321/H, 347/H, 904L, 330, 254SMO, 410. In duplex grades, we can supply 2205 and 2507. Some nickel grades are also supplied.

Grade: TP304,TP304L,TP304H,TP316,TP316L,TP316Ti,TP309,TP310S,TP321,TP321H, TP347, TP347H, TP405, TP410, TP430

Size Range:OD: 6-762mm, Thickness: 0.5-50mm,

Max length: 18000mm

Schedules: 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Surface: BA, 2B, NO.1, NO.4, 4K, HL, 8K

Materials:

304 (0Cr18Ni9),304L (00Cr19Ni10),1Cr18Ni9Ti,321H (0Cr18Ni10Ti),310S (0Cr25Ni20),347H (0Cr19Ni11Nb),316 (0Cr17Ni12M02),316L (00Crl 7Ni14M02),316Ti (0Crl 7Ni12M02Ti),317 00Crl 9Ni13M03) ,S31803,S32205,S32750,S32760 etc

Standards:GB/T14975, GB/T14976, GB13296, GB9948, GB5310,GB/T21833,GB/T12771,ASTM A312,ASTM A213, ASTMA269, ASTM A789, ASTM A790, ASTM A511, ASTM A376, ASTM A688, JIS 3463, JIS 3459, DIN 2462, DIN 17458, DIN 17456, EN 10297-2, EN 10216-5, GOST 9940, GOST 9941, ASTM A450, ASTM A999, JIS G3459

Email to us

Email to us

|

Product Name |

Executive Standard |

Dimension |

Steel Code / Steel Grade |

|

Seamless Austenitic Stainless Steel Pipes |

ASTM A312/A312M, ASME SA312/SA312M |

OD: 6.0~914.0mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

|

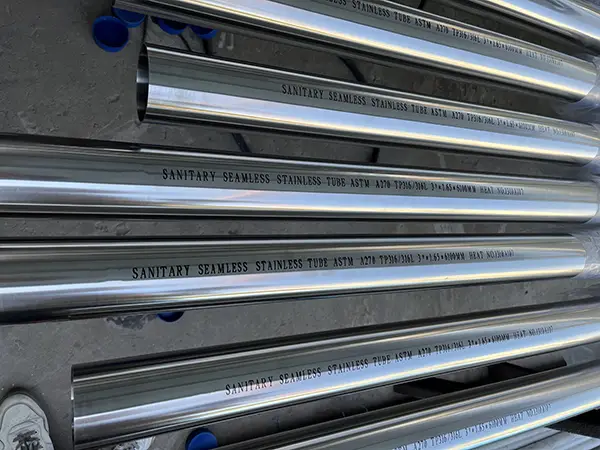

Seamless Austenitic Stainless Steel Tubing for General Service |

ASTM A269, ASME SA269 |

OD: 6.0~50.8mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

|

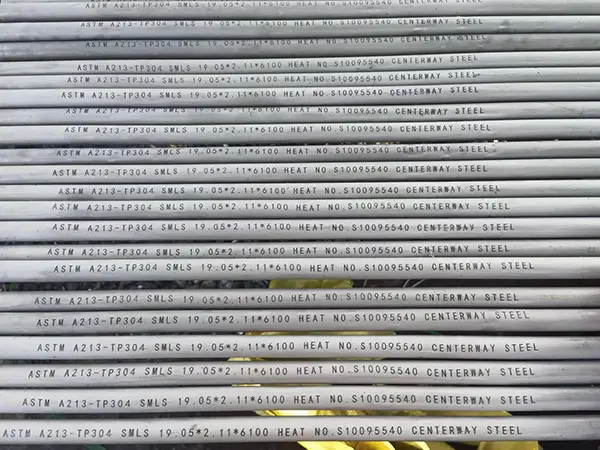

Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes |

ASTM A213/A213M, ASME SA213/SA213M |

OD: 6.0~50.8mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

|

Seamless Duplex Stainless Steel Tubing for General Service |

ASTM A789 / A789M |

OD: 19.0~60.5mm |

S31803, S32205, S32750 |

|

Seamless Duplex Stainless Steel Pipes |

ASTM A790 / A790M |

OD: 3/4"~10" |

S31803, S32205, S32750 |

|

Seamless Stainless Steel Mechanical Tubing |

ASTM A511 |

OD: 6.0~50.8mm |

MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

|

Seamless Stainless Steel Tubes for Pressure Purposes |

EN 10216, DIN 17456, 17458 |

OD: 6.0~914.0mm |

1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

Austenitic steel

|

TP304 |

General-purpose stainless steel with good corrosion resistance for most applications. Used for: Bar rails, Boat |

|

TP304H |

Higher carbon content than 304L, for increased strength, particularly at elevated temperatures. |

|

TP304L |

Chemical plant and food processing equipment, where freedom from sensitization is required in plate thicknesses |

|

TP316/316L |

Used where higher corrosion resistance is required. Boat railings, Canopy supports, Chemical tubing, Column covers, |

|

TP316H |

Similar oxidation resistance to TP 316. Main areas of application: Heat exchangers, furnaces, chemical and |

|

TP321 |

Heat exchanger tubing, Chemical processing tubing, Pressure tank tubing. Suitable for heat resisting applications |

|

TP321H |

This is the high carbon version of TP 321 which ensures greater creep resistance. Behaves much the same as TP 321 |

|

TP316Ti |

A titanium stabilized version of 316 used where good resistance to intergranular corrosion and high temperature |

|

TP317 |

Chemical processing tubing, Dyeing equipment, Ink manufacturing equipment, Pulp & paper manufacturing |

|

TP347HFG |

Mainly used for boilers in the termal power plant, reheaters and superheaters |

Super-Austenitic steel

TP904L

High resistance to general corrosion in e.g. sulphuric and acetic acids, crevice corrosion, stress corrosion cracking, pitting in chloride bearing solutions.

Ferritic and Martensitic Steel

|

TP405 |

Used for applications where hardening upon cooling from high temperatures must be avoided. Has excellent |

|

TP410 |

General purpose grade for use in mildly corrosive environments |

|

TP430 |

Mechanical & structural tubing, Architectural tubing, Heat exchanger tubing, Condensers, Re-heaters, Evaporators. |

Duplex

|

S31803 |

Typically used in heat exchangers, gas scrubbers, fans, chemical tanks, flowlines, marine and refinery applications. |

|

S32750 |

Used in oil & gas, chemical process, power industries. At that heat-exchangers are main application. |

|

S31254 |

With high levels of chromium, molybdenum, and nitrogen is especially suited for high-chloride environments such as brackish water, seawater and other high-chloride process streams. |

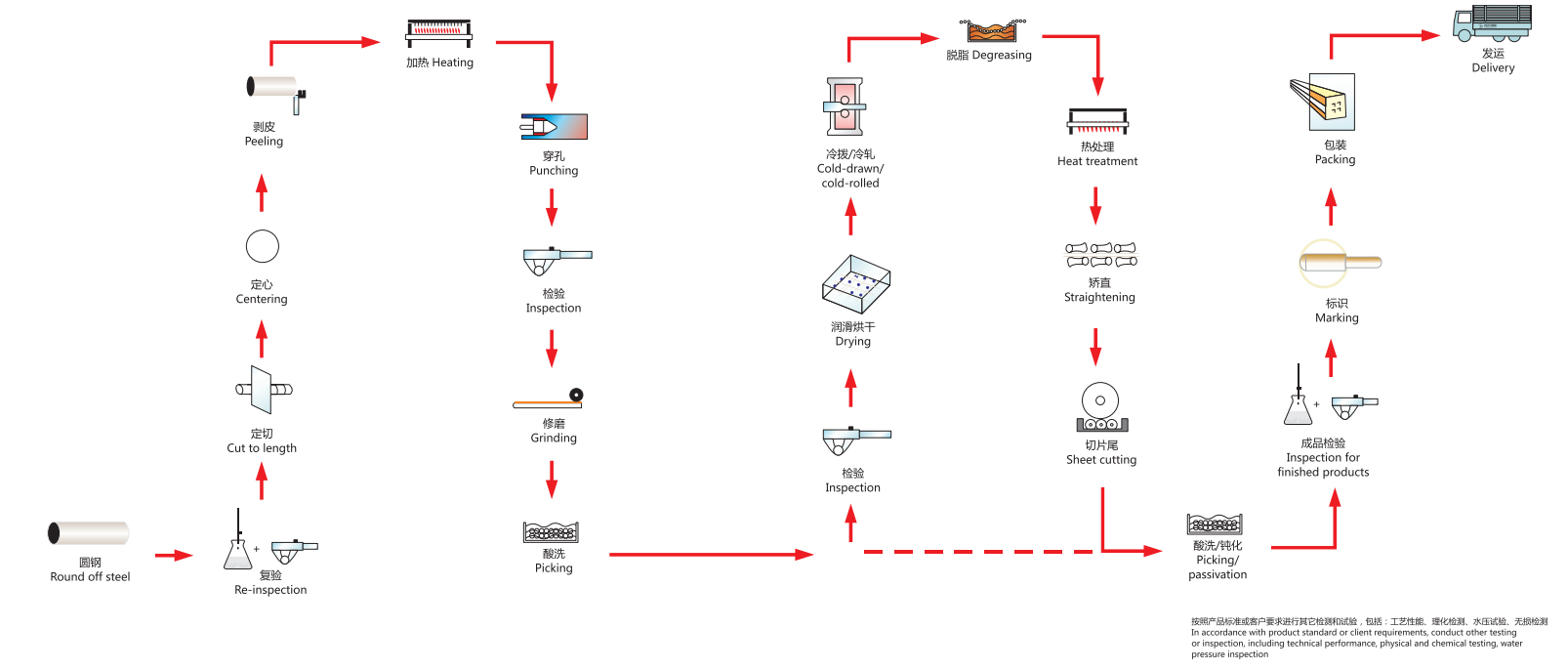

Manufacturing Process of Stainless Steel Pipe

Seamless stainless steel pipe is made from solid stainless steel bar which is called billet. By using different processing techniques such as extruding, gun drilling or piercing, the steel bars are produced to be steel tubes.

1. Firstly, the billets would be inspected exactly.

2. Then put the billets into the heat to raise the temperature.

3. The hot billets would then be pierced through the center with a mandrel. Through this procedure, the bar shape billet becomes hollow shape billet.

4. The next step is rolling and stretching the hollow billet. The billet is precisely rolled and stretched until it meets all the specifications with length, diameter and wall thickness according to requirements.

Application

Stainless steel seamless pipe can resist high temperatures for cleanliness and maintain the purity of materials which contact stainless steel directly. Stainless steel pipe and tubing are used in chemical plants, aviation fields, marine equipment, cryogenic transportation, medical and architectural industries.

- Chemical plants

- Aviation fields

- Marine equipment

- Cryogenic transportation

- Medical & architectural industries