Products

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Standards

ASTM A403 Standard specification covers the standard for wrought austenitic stainless steel fittings for pressure piping applications.

Grade:

ASTM A304, 304L, 316, 316L, 316Ti, 317L, 321, 321H, 347, 347H, 904L, 254 SMO (W1.4301, 1.4306, 1.4948, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4878, 1.4550, 1.4845, 1.4539, 1.4547 etc.).

Size Range:

Elbow:Size Range: 1/2”- 24”( DN 21.3 - DN 610) for Seamless;26”- 96”( DN 660 - DN 2438.4) for Welded.

Reducer:Size Range: 1/2″to 24″

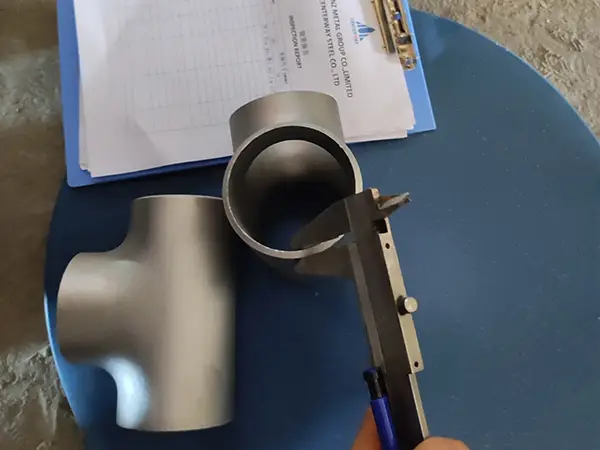

Tee:Size Range: 1/2”- 24”( DN 21.3 - DN 610) for Seamless;26”- 72”( DN 660 - DN 1828.8) for Welded.

Cap:Size range: 1/2 to 56 inches (DN15 to DN1400),Max. wall thickness: 200mm

Type:Seamless / Welded

Email to us

Email to us

Stainlessbuttweld pipe fittings is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment.Stainlessbuttweld pipe fittings are manufactured in accordance with ASTM A403

Stainlessbuttweld pipe fittings are available as elbows, tees, caps, reducers etc. These fittings are the most common type of welded pipe fittings and are specified by nominal pipe size and pipe schedule. Buttweld fittings use seamless or welded pipe as the starting material and are formed (through multiple processes) to get the shape of elbows, tees and reducers etc. Welded butt weld fittings are more common in stainless steel due to cost advantage. SCH 10 fittings are also more common in stainless steel butt weld fittings.

ASTM A403-ASTM A403 Standard specification covers the standard for wrought austenitic stainless steel fittings for pressure piping applications.

Chemical Composition (%)

|

Steel No. |

Type |

C |

Si |

S |

P |

Mn |

Cr |

Ni |

Mo |

Other |

ób |

ós |

δ5 |

|

WP304 |

0.08 |

1 |

0.03 |

0.045 |

2 |

18-20 |

8-11 |

|

|

515 |

205 |

28 |

|

|

WP304H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

18-20 |

8-11 |

|

|

515 |

205 |

28 |

|

|

WP304L |

0.035 |

1 |

0.03 |

0.045 |

2 |

18-20 |

8-13 |

|

|

485 |

170 |

28 |

|

|

WP304LN |

0.03 |

0.75 |

0.03 |

0.045 |

2 |

18-20 |

8-10.5 |

|

N2:0.1-0.16 |

515 |

205 |

28 |

|

|

WP304N |

0.08 |

0.75 |

0.03 |

0.045 |

2 |

18-20 |

8-11 |

|

N2:0.1-0.16 |

550 |

240 |

28 |

|

|

WP309 |

0.15 |

1 |

0.03 |

0.045 |

2 |

22-24 |

12-15 |

|

|

515 |

205 |

28 |

|

|

WP310 |

0.15 |

1.5 |

0.03 |

0.045 |

2 |

24-26 |

19-22 |

|

|

515 |

205 |

28 |

|

|

WP316 |

0.08 |

1 |

0.03 |

0.045 |

2 |

16-18 |

10-14 |

2-3 |

|

515 |

205 |

28 |

|

|

WP316H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

16-18 |

10-14 |

2-3 |

|

515 |

205 |

28 |

|

|

WP316LN |

0.03 |

0.75 |

0.03 |

0.045 |

2 |

16-18 |

11-14 |

2-3 |

N2:0.1-0.16 |

515 |

205 |

28 |

|

|

WP316L |

0.035 |

1 |

0.03 |

0.045 |

2 |

16-18 |

10-16 |

2-3 |

|

485 |

170 |

28 |

|

|

WP316N |

0.08 |

0.75 |

0.03 |

0.045 |

2 |

16-18 |

11-14 |

2-3 |

N2:0.1-0.16 |

550 |

240 |

28 |

|

|

WP317 |

0.08 |

1 |

0.03 |

0.045 |

2 |

18-20 |

11-15 |

3-4 |

|

515 |

205 |

28 |

|

|

WP317L |

0.03 |

1 |

0.03 |

0.045 |

2 |

18-20 |

11-15 |

3-4 |

|

515 |

205 |

28 |

|

|

WP321 |

0.08 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ti:5C-0.7 |

515 |

205 |

28 |

|

|

WP321H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ti:4C-0.7 |

515 |

205 |

28 |

|

|

WP347 |

0.08 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Nb+Ta:10C-1.1 |

515 |

205 |

28 |

|

|

WP347H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Nb+Ta:8C-1 |

515 |

205 |

28 |

|

|

WP348 |

0.08 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ta:0.1 |

515 |

205 |

28 |

|

|

WP348H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ta:0.1 |

515 |

205 |

28 |

|

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The sum of Cr and Mo shall not exceed 0.32%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Mechanical properties

|

Grade |

UNS |

Tensile Strength, min |

Yield Strength,min |

Elongation min % in 4D |

|||

|

ksi |

MPa |

ksi |

MPa |

Longit % |

Trans% |

||

|

ALL |

ALL |

75 |

515 |

30 |

205 |

28 |

20 |

|

304L |

S30403 |

70 |

485 |

25 |

170 |

28 |

20 |

|

316L |

S31603 |

70 |

485 |

25 |

170 |

28 |

20 |

|

304N |

S30451 |

80 |

550 |

35 |

240 |

28 |

20 |

|

316N |

S31651 |

80 |

550 |

35 |

240 |

28 |

20 |

|

S31726 |

80 |

550 |

35 |

240 |

28 |

20 |

|

|

XM-19 |

S20910 |

100 |

690 |

55 |

380 |

28 |

20 |

|

S31254 |

94-119 |

650-820 |

44 |

300 |

28 |

20 |

|

|

S34565 |

115 |

795 |

60 |

415 |

28 |

20 |

|

|

S33228 |

73 |

500 |

27 |

185 |

28 |

20 |

|