Products

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

ASTM A182–Specification for Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High Temperature Service

Size:1/2” to48” ,SCH5S-SCH XXS,Welded and seamless

Specification: ASTM A182 / A403 & ASME SA182 / SA403

Grades: 201, 202, 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

Email to us

Email to us

Types of stainless steel flange

Blind Flange:These flanges do not have a bore. It is used to blind off a flange or even a valve. When used at the end of a pipe or fitting, it provides an easy to open access for further extension of the pipe. The blind flange and its bolts are stressed more than any other flange.

Lap Joint Flange:This flange is used with a lap joint stub end fitting. It is similar to a slip-on flange, but with two differences. The radius and the flat face, both allow the flange to secure against the stub end fitting. This is useful where alignment of bolt holes is difficult, such as with spools to be attached to flange nozzles of vessels. A lap joint is used in low pressure applications and not suitable where high external of heavy loads are present.

Slip-on Flange:A slip on flange is designed to slip over the end of pipe. It allows for easy positioning before welding. Both the inside and outside of the pipe is welded on the slip on flange. See picture on the right. The pipe is generally inserted all the way, inside the slip on flange, leaving only the gap equivalent to wall thickness of pipe. These flanges are also knows as ANSI Flange or ASME B16.5 Flange

Socket Weld Flange:This is similar to a slip-on flange, except they have a bored and counter bore. The counter bore allows the pipe to fit into the socket/counter bore. The bore of the flange is the same diameter as the inside of the pipe. These flanges were first designed for small diameter, high pressure pipe.

Threaded Flange:It is similar to a slip-on Flange, but has internal threads. It is normally used for low pressure and not used where temperature or stress is very high. Threaded flange is also called screwed flange or screwed-on flange. This type of flange is used where welding is not an option. Threaded flange is most commonly used on low pressure applications and smaller pipes (up to 4" nominal).

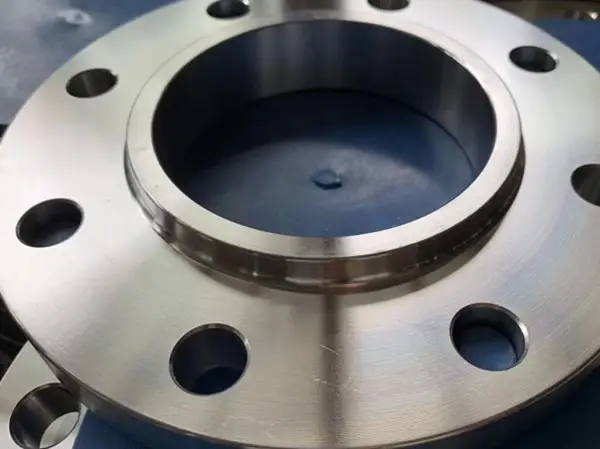

Weld Neck Flange:This flange type is designed to be connected by a butt weld connection to the pipe or equipment requiring a flange joint. Welding neck provides good service under variety of temperature and pressure applications. A weld neck flange must specifiy the pipe schedule for the bore. Due to the welding neck, it is a popular choice on pressure vessels and for creating man-holes etc. These flanges are also knows as ANSI Flange or ASME B16.5 Flange

|

The type of flange |

The type of sealing face |

Pressure Class(PN,MPA) |

|

Plate flange(PL) |

Raise Face(RF) |

0.25-2.5 |

|

Flat Face( FF) |

0.25-1.6 |

|

|

Slip on flange(SO) |

Raise Face(RF) |

0.6-4.0 |

|

Flat Face( FF) |

0.6-1.6 |

|

|

male and female face (MFM) |

1.0-4.0 |

|

|

Tongue and groove face (TG) |

1.0-4.0 |

|

|

Welding Neck Flange(WN) |

Raise Face(RF) |

1.0-25.0 |

|

male and female face (MFM) |

1.0-16.0 |

|

|

Tongue and groove face (TG) |

1.0-16.0 |

|

|

Ring Joint Face(RTJ) |

6.3-25.0 |

|

|

Flat Face( FF) |

1.0-1.6 |

|

|

Integral type flange(IF) |

Raise Face(RF) |

0.6-25.0 |

|

male and female face (MFM) |

1.0-16.0 |

|

|

Tongue and groove face (TG) |

1.0-16.0 |

|

|

Ring Joint Face(RTJ) |

6.3-25.0 |

|

|

Flat Face( FF) |

0.6-1.6 |

|

|

Socket Weld Flange(SW) |

Raise Face(RF) |

1.0-10.0 |

|

male and female face (MFM) |

1.0-10.0 |

|

|

Tongue and groove face (TG) |

1.0-10.0 |

|

|

Thread Flange(Th) |

Raise Face(RF) |

0.6-4.0 |

|

Flat Face( FF) |

0.6-1.6 |

|

|

Lap joint Flange(LP) |

Raise Face(RF) |

0.6-1.6 |

|

male and female face (MFM) |

1.0-1.6 |

|

|

Tongue and groove face (TG) |

1.0-1.6 |

|

|

Blind flange(BL) |

Raise Face(RF) |

0.25-25.0 |

|

male and female face (MFM) |

1.0-16.0 |

|

|

Tongue and groove face (TG) |

1.0-16.0 |

|

|

Ring Joint Face(RTJ) |

6.3-25.0 |

|

|

Flat Face( FF) |

0.25-1.6 |