Products

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2" (15 NB) to 48" (1200NB)

Class range: Class 150, Class 300, 400, 600, 900, 1500, 2500(# or LB). PN 2.5 to PN 250.

Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

Material & Grades

Stainless Steel Slip On Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Slip On Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Alloy Steel Slip On Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Slip on flange, also called SO flange. It's a kind of flange slides over the pipe with internal design is slightly larger than the pipe. Since the inner diameter of the flange is slightly larger than the outer diameter of the pipe, the SO flange can be directly connected to equipment or pipe by fillet weld at the top and bottom of the flange. It is used to insert the pipe into the inner hole of the flange. Slip-On Pipe Flanges. As made obvious by their name, these pipe flanges slip over the pipe. They're manufactured with an inside diameter that is slightly bigger than the pipe's outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange.

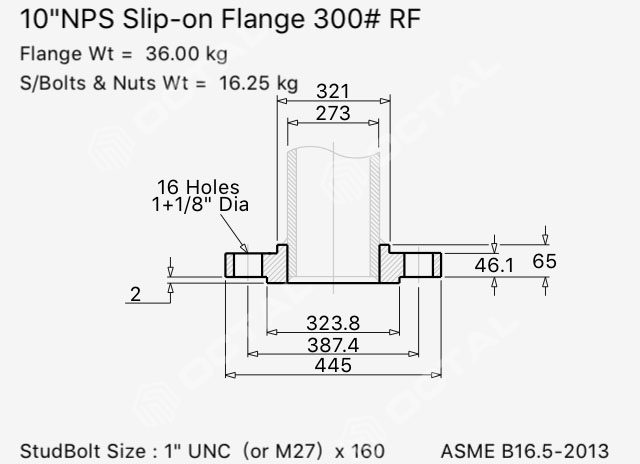

Raised Face Slip On Flange

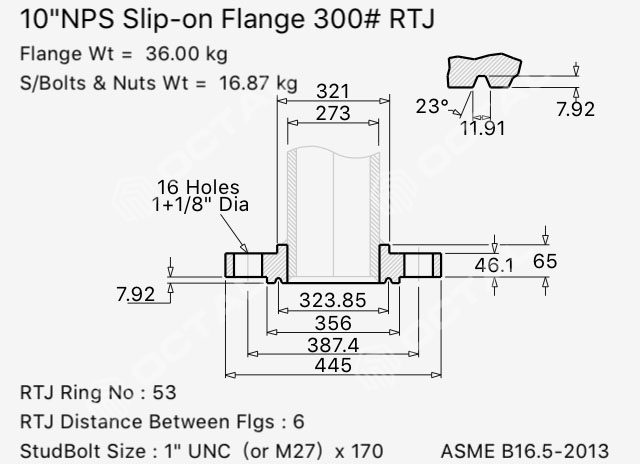

RTJ Slip On Pipe Flanges

Chemical

|

Type |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mb |

|

302 |

0.15 |

2.00 |

0.045 |

0.030 |

1.00 |

17.00/19.00 |

8.00/10.00 |

– |

|

304 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

18.00/20.00 |

8.00/10.50 |

– |

|

304L |

0.03 |

2.00 |

0.045 |

0.030 |

1.00 |

18.00/20.00 |

8.00/12.00 |

– |

|

309 |

0.20 |

2.00 |

0.045 |

0.030 |

1.00 |

22.00/24.00 |

12.00/15.00 |

– |

|

309S |

0.08 |

2.00 |

0.045 |

– |

1.00 |

22.00/24.00 |

– |

– |

|

310 |

0.25 |

2.00 |

0.045 |

0.030 |

1.5 |

24.00/26.00 |

19.00/22.00 |

– |

|

310S |

0.08 |

2.00 |

0.045 |

0.030 |

1.5 |

24.00/26.00 |

19.00/22.00 |

– |

|

316 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

16.00/18.00 |

10.00/14.00 |

2.00/3.00 |

|

316L |

0.03 |

2.00 |

0.045 |

0.030 |

1.00 |

16.00/18.00 |

10.00/14.00 |

2.00/3.00 |

|

317 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00/1.00 |

18.00/20.00 |

11.00/15.00 |

3.00/4.00 |

|

317L |

0.03 |

2.00 |

0.045 |

0.030 |

0.75 |

18.00/20.00 |

11.00/15.00 |

3.00/4.00 |

|

321 |

0.08 |

2.00 |

0.040 |

0.030 |

1.00 |

17.00/19.00 |

9.00/12.00 |

0.75/0.75 |

|

347 |

0.08 |

2.00 |

0.040 |

0.030 |

0.5/1.00 |

17.00/19.00 |

9.00/12.00 |

0.5/0.75 |

Equivalent Grades

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

SS 304 |

1.4301 |

S30400 |

SUS 304 |

304S31 |

08Х18Н10 |

Z7CN18‐09 |

X5CrNi18-10 |

|

SS 316 |

1.4401 |

S31600 |

SUS 316 |

316S31 |

- |

Z7CND17‐11‐02 |

X5CrNiMo17-12-2 |

Mechanical & Physical Properties

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |