Products

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

Centerway steel specializes in the production of the stainless steel pipe and fittings, and large inventory of resources, Factory direct sales

|

Standards |

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

|

Size |

1/2" NB TO 48" NB |

|

Designation |

A 182 / A 240, SA 182 / SA 240 |

|

Class |

150#, 300#, 400#, 600#, 900#, 1500# & 2500#. |

|

Grade |

ASTM A182 F304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L ETC. |

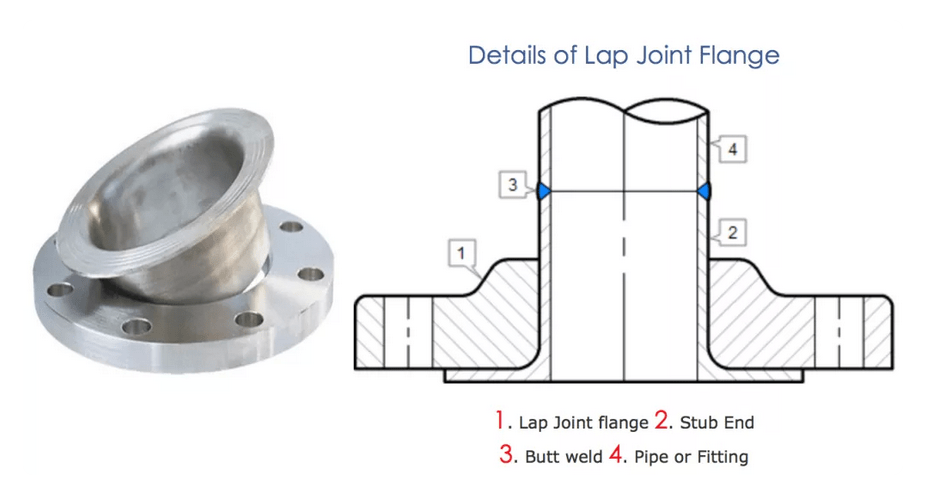

Lap Joint Flanges (LJ Flanges) are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges.

Lap joint flange datasheets

The datasheets we have on this site are shown below. For simplicity sake, only datasheets that adhere to B16.5 are shown. ASME B16.5 covers flange dimensions from½”to 24”. For sizes larger than this (ASME B16.47 Series A & B), please visit our flange datasheets page.

|

Class |

Flat Face |

|

ANSI 150 |

Lap Joint, ANSI Class 150 (in) |

|

ANSI 300 |

Lap Joint, ANSI Class 300 (in) |

|

ANSI 400 |

Lap Joint, ANSI Class 400 (in) |

|

ANSI 600 |

Lap Joint, ANSI Class 600 (in) |

|

ANSI 900 |

Lap Joint, ANSI Class 900 (in) |

|

ANSI 1500 |

Lap Joint, ANSI Class 1500 (in) |

|

ANSI 2500 |

Lap Joint, ANSI Class 2500 (in) |

Mechanical Strength

|

Type |

UNS |

Tensile |

Yield |

Elongation |

Hardness |

Hardness |

|

302 |

S30200 |

75 |

30 |

40% in 2″ |

183 |

88 |

|

304 |

S30400 |

75 |

30 |

40% in 2″ |

183 |

88 |

|

304L |

S30403 |

70 |

30 |

40% in 2″ |

183 |

88 |

|

309 |

S30900 |

75 |

30 |

40% in 2″ |

217 |

95 |

|

309S |

S30908 |

75 |

30 |

40% in 2″ |

217 |

95 |

|

310 |

S31000 |

75 |

30 |

40% in 2″ |

217 |

95 |

|

310S |

S31008 |

75 |

30 |

40% in 2″ |

217 |

95 |

|

316 |

S31600 |

75 |

30 |

40% in 2″ |

217 |

95 |

|

316L |

S31603 |

70 |

25 |

35% in 2″ |

217 |

95 |

|

317 |

S31700 |

75 |

30 |

35% in 2″ |

217 |

95 |

|

317L |

S31703 |

75 |

30 |

35% in 2″ |

217 |

95 |

|

321 |

S32100 |

75 |

30 |

40% in 2″ |

183 |

88 |

|

347 |

S34700 |

75 |

30 |

40% in 2″ |

183 |

88 |

Equivalent Grades

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

SS 304 |

1.4301 |

S30400 |

SUS 304 |

304S31 |

08Х18Н10 |

Z7CN18‐09 |

X5CrNi18-10 |

|

SS 316 |

1.4401 |

S31600 |

SUS 316 |

316S31 |

- |

Z7CND17‐11‐02 |

X5CrNiMo17-12-2 |

Chemical Composition

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

SS 304 |

0.08 max |

2 max |

0.75 max |

0.040 max |

0.030 max |

18 – 20 |

– |

8 – 11 |

|

|

SS 316 |

0.08 max |

2 max |

0.75 max |

0.045 max |

0.030 max |

16 – 18 |

2 – 3 |

10 – 14 |

0.1 max |

Mechanical & Physical Properties

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |