News

Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

Are you risking your project safety by guessing the limits of your pipeline materials? Leaks and ruptures cause massive delays, environmental damage, and can ruin your reputation in the industry. To determine the correct stainless steel tubing pressure rating, you must compare the tube’s wall thickness against its outside diameter. Always ensure the tubing’s working pressure is lower than the system’s maximum limit, typically maintaining a 4:1 safety ratio against the burst pressure for maximum safety.

Many people look at a standard chart and think they have the answer. However, real-world application is much more complex than a piece of paper. I will explain the critical details that keep your system safe.

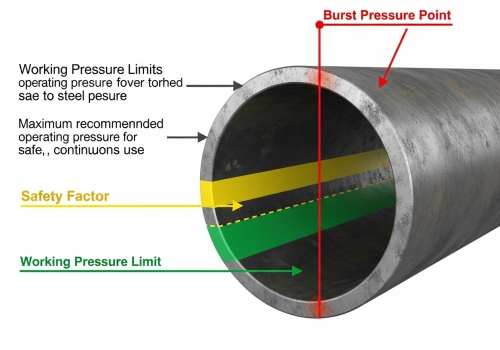

Confusing the safe operating limit with the failure limit is the most common reason for catastrophic system failure in our industry. The working pressure is the maximum force the tube can handle daily, while the burst pressure is the point where the metal actually breaks. For a safe stainless steel tubing pressure rating, industry standards usually require the burst pressure to be four times higher than the working pressure.

I have seen many young engineers make a simple mistake. They look at the test results of a pipe and see a high number. They think, "Great, this pipe can handle 10,000 PSI." But that was the burst pressure, not the working pressure. In my years at Centerway Steel, I have learned that safety is about margins. The "Working Pressure" is your safe zone. This is the pressure the tubing experiences during normal operation. The "Burst Pressure" is the absolute limit. At this point, the tensile strength of the material fails, and the tube ruptures. We follow a strict rule for instrumentation tubing. The burst pressure must be at least 4 times the working pressure. This 4:1 ratio accounts for pressure spikes, vibration, and material fatigue over time. (Insert personal story here about a time a client ignored the safety margin and faced a leak during testing). Here is a simple breakdown of the relationship:

| Pressure Type | Definition | Safety Factor |

|---|---|---|

| Working Pressure | Safe for daily operation | 100% of Rated Load |

| Test Pressure | Used for inspection (Hydrotest) | 1.5x Working Pressure |

| Burst Pressure | Point of material failure | 4x Working Pressure |

You might think a bigger pipe automatically handles more pressure, but in the world of physics, the opposite is often true. The relationship is simple: thicker walls increase strength, while larger diameters actually decrease the stainless steel tubing pressure rating. You need to balance the wall thickness with the outer diameter to find the sweet spot for your specific project.

This is where things get technical, but I will keep it simple. Imagine blowing up a balloon. The larger it gets, the thinner the skin becomes, and the easier it pops. Steel tubing works in a similar way. If you have two tubes with the same wall thickness, the one with the smaller diameter is stronger. It can handle higher pressure. If you need a large diameter pipe to handle high pressure, you must increase the wall thickness significantly. This increases the weight and the cost. Also, you must consider how the tube is made. Seamless tubing is a solid piece of metal. Welded tubing is rolled and welded. Because of the weld seam, welded tubing is generally rated at 80% of the pressure of seamless tubing. At Centerway Steel, we help you calculate this. We use standard formulas to ensure you do not overpay for thickness you do not need, or buy thin tubes that will fail. Here is a general reference for 316/316L Seamless Tubing (values are approximate for illustration):

| Tube OD (inches) | Wall Thickness (inches) | Working Pressure (PSI) |

|---|---|---|

| 1/4 | 0.035 | 5,100 |

| 1/4 | 0.049 | 7,500 |

| 1/2 | 0.049 | 3,700 |

| 1/2 | 0.065 | 5,100 |

| 1 | 0.083 | 3,100 |

A pipe that works perfectly in a cool laboratory might fail completely in a hot desert oil field or a freezing ocean platform. Yes, heat significantly lowers the strength of steel. You must apply a derating factor to the standard stainless steel tubing pressure rating when operating above room temperature. Also, corrosive environments like saltwater require higher alloy grades to maintain integrity over time.

When I talk to purchasing managers, I always ask: "Where will this pipe live?" If your project is in the Middle East, the ambient temperature is high. If the fluid inside the pipe is hot steam, the metal gets softer. A stainless steel tube rated for 5,000 PSI at room temperature (70°F) is not rated for 5,000 PSI at 600°F. It might only be safe for 3,500 PSI. We call this "Temperature Derating." You have to multiply the standard pressure rating by a factor to get the real limit. (Insert personal story here about helping a client in Southeast Asia choose the right alloy for a hot, humid environment). Also, corrosion is a silent killer. If you are near the ocean, chloride in the air eats standard steel. If you are pumping sour gas, H2S attacks the metal structure. In these cases, pressure rating is not the only factor. You need the right material, like 316L or Duplex stainless steel, to stop the wall from getting thinner over time. Here is how temperature reduces the pressure rating for Type 316 Stainless Steel:

| Temperature (°F) | Derating Factor |

|---|---|

| 100°F | 1.00 (No change) |

| 200°F | 0.96 |

| 400°F | 0.86 |

| 600°F | 0.82 |

| 800°F | 0.76 |

| 1000°F | 0.69 |

So, at 1000°F, your pipe loses roughly 30% of its pressure holding capability. We must account for this during the purchasing phase to avoid accidents later.

To keep your project safe, calculate the stainless steel tubing pressure rating by checking the diameter and wall thickness, then reduce that number based on your operating temperature. Always prioritize the 4:1 safety margin.