News

Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

Are you struggling to choose the right piping material for your construction project? Selecting the wrong grade can lead to costly corrosion and structural failures later on. 304 stainless steel pipe properties include excellent corrosion resistance, high durability, and good formability. Known as "18/8" steel, it withstands various environments, making it ideal for construction, water treatment, and chemical processing. It balances cost and performance effectively for most industrial applications.

I know how confusing technical datasheets can be when you are trying to source materials. I want to break down exactly what makes this grade the industry standard so you can make a safe purchasing decision.

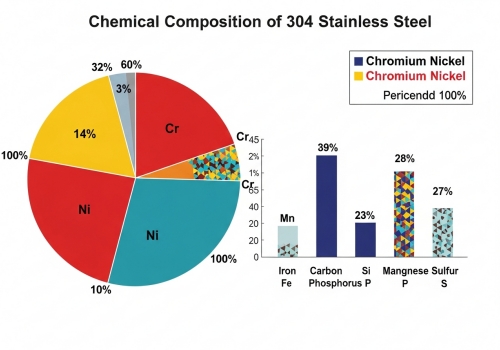

You might wonder why specific percentages of metals matter so much. Without the right chemical balance, your pipes won't survive the harsh environments they face daily. The composition is defined by roughly 18% chromium and 8% nickel. This mixture creates an austenitic structure that provides distinct 304 stainless steel pipe properties, including rust resistance and toughness. It also contains small amounts of carbon and manganese.

I have been in the steel industry since 1996, and I see many clients confused about the "18/8" name. It is simple. It stands for the 18% Chromium and 8% Nickel found in the alloy. This specific recipe is what gives the pipe its ability to resist rust and stay strong. The Chromium reacts with oxygen to form a thin skin on the pipe. This skin protects the metal underneath. The Nickel helps the steel remain ductile, so we can shape it without breaking it. There are also variations like 304L and 304H. The "L" stands for Low Carbon. If you are welding heavy pipes, I always suggest 304L because it stops the steel from weakening at the weld joint. The "H" stands for High Carbon, which is better for very high temperatures. Here is a table to help you compare the standard composition we use at Centerway Steel.

| Element | Grade 304 (%) | Grade 304L (%) |

|---|---|---|

| Carbon (C) | 0.08 max | 0.030 max |

| Manganese (Mn) | 2.00 max | 2.00 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.030 max | 0.030 max |

| Silicon (Si) | 0.75 max | 0.75 max |

| Chromium (Cr) | 18.00 - 20.00 | 18.00 - 20.00 |

| Nickel (Ni) | 8.00 - 10.50 | 8.00 - 12.00 |

| Nitrogen (N) | 0.10 max | 0.10 max |

High pressure and extreme temperatures can destroy inferior piping systems. You need to know if your materials can handle the physical stress of your project. Mechanically, these pipes offer high tensile strength and yield strength. Physically, 304 stainless steel pipe properties include the ability to withstand extreme temperatures, though they are not magnetic. They are easy to fabricate and clean, adding to their versatility.

When we talk about strength, we look at how much pulling force the pipe can take before it breaks. For grade 304, this is about 515 MegaPascals (MPa). This makes it very reliable for structural support in your construction projects. It is also important to know that you cannot harden this steel by using heat treatment. If you heat it and cool it, it stays soft. The only way to make it harder is by "cold working," which means shaping it while it is at room temperature. Another key point is temperature resistance. These pipes resist oxidation up to 925°C in continuous service. But, I must warn you about a range between 425°C and 860°C. If you use standard 304 in this range, it might corrode faster later if water touches it. In that specific case, you should use 304L. Also, keep in mind that unlike regular carbon steel, 304 stainless steel is generally non-magnetic. This is useful for projects involving sensitive electronics.

| Property | Value (Typical) |

|---|---|

| Tensile Strength (MPa) | 515 min |

| Yield Strength 0.2% Proof (MPa) | 205 min |

| Elongation (% in 50mm) | 40 min |

| Hardness (Rockwell B) | 92 max |

| Density (kg/m³) | 8000 |

| Melting Point (°C) | 1400 - 1455 |

Rust is the enemy of any long-term infrastructure project. If you ignore the environment your pipes will sit in, you risk total system failure. This grade forms a passive oxide layer that blocks rust in most atmospheric conditions. While excellent for fresh water and acids, the 304 stainless steel pipe properties might falter in high-chloride marine environments, where grade 316 is usually a better choice.

The main reason my customers buy 304 pipes is for the corrosion resistance. It handles ordinary rusting, food acids, and organic chemicals very well. We supply a lot of this material to the food processing and dairy industries because it is easy to clean and does not contaminate the product. In the construction industry, it stays bright and shiny for years as handrails or architectural panels. However, you must be careful with salt. I always tell my partners that if the project is near the ocean or involves seawater, 304 is not enough. The chlorides in the salt will attack the metal and cause "pitting." This looks like small holes eating into the pipe. For those jobs, you need grade 316. But for most inland oil, gas, and urban pipeline networks, 304 is the most cost-effective choice. It gives you the protection you need without the extra cost of marine-grade steel. Applications where 304 excels:

· Water Treatment: It resists the chemicals used to clean water.

· Building Structures: It looks good and lasts a long time.

· Brewery Equipment: It is safe for beverages and easy to sanitize.

304 stainless steel offers the best balance of strength, corrosion resistance, and cost. As Centerway Steel, we ensure every pipe meets these high standards for your global projects.