News

Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

Corrosion eats your budget and replacing flanges halts your production. You need a piping solution that lasts longer in harsh environments and costs less over time. Duplex stainless steel flanges offer a perfect balance of ferrite and austenite, providing double the strength of standard 304 or 316 steel. They resist chloride stress corrosion cracking effectively, making them the ideal, cost-saving choice for aggressive marine and chemical environments.

I have seen many project managers struggle with material selection. They often choose standard stainless steel to save money upfront, only to pay more later for repairs. I want to share why upgrading your specs to duplex materials is actually a better financial decision for your company.

Are you tired of reading constant maintenance reports about leaks? Weak flanges cause safety risks and expensive downtime that you cannot afford. The main advantage is superior resistance to pitting and stress corrosion. Their unique microstructure ensures they handle high pressure and physical stress much better than common austenitic grades, significantly extending your project's lifespan.

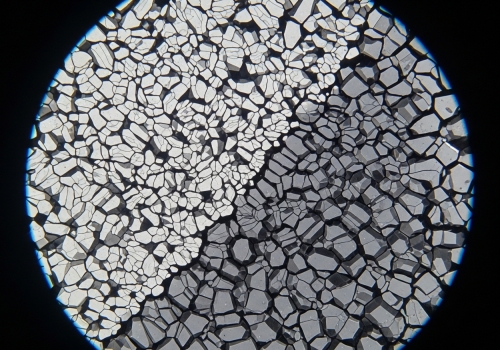

When we talk about duplex stainless steel flanges, we are talking about a material that is not just "harder." It is scientifically smarter. The word "Duplex" means it has a two-phase microstructure. It is roughly 50% ferritic and 50% austenitic. This combination solves the weaknesses of both individual types. Ferritic steel is strong but brittle; austenitic steel is ductile but prone to stress cracking. By combining them, we give you the best of both worlds. For an EPC purchasing manager, this translates to reliability. In my 20+ years at Centerway Steel, I have supplied these components to offshore rigs where saltwater sprays constantly. Standard 316L stainless steel often cracks under this stress (Stress Corrosion Cracking or SCC). Duplex does not. Furthermore, the yield strength of duplex grades is typically double that of austenitic stainless steels. This high strength allows us to suggest lighter, thinner flanges for your designs without sacrificing pressure ratings. This reduction in weight helps you save on transportation costs and makes installation easier for your team on-site. Here is a quick comparison of mechanical properties to help you visualize the difference:

| Property | 316L Stainless Steel | Duplex 2205 (UNS S31803) | Advantage |

|---|---|---|---|

| Yield Strength (MPa) | ~170 | ~450 | Duplex is >2x stronger |

| Tensile Strength (MPa) | ~485 | ~620 | Handles higher loads |

| Hardness (Brinell) | ~217 Max | ~293 Max | Better wear resistance |

| Corrosion Resistance | Moderate | Excellent | Longer service life |

High material prices always hurt your bottom line. You worry about going over budget and explaining the extra costs to your directors. Because duplex steel is stronger, you can often use thinner sections to achieve the same pressure rating. This reduces the total weight and material cost compared to high-alloy alternatives, saving you money immediately.

Many buyers assume that because duplex stainless steel flanges offer higher performance, they must be the most expensive option. This is a common misconception. The price of stainless steel is heavily driven by the price of Nickel. Standard austenitic steels like 316 contain a high percentage of Nickel (around 10-14%). Duplex steels, however, use a lower Nickel content (around 5-6%) and substitute it with Nitrogen to maintain the structure. Since Nickel prices are volatile on the global market, choosing Duplex helps stabilize your project estimates. But the savings go deeper than just the raw material price per kilogram. We must look at the "Life Cycle Cost" (LCC).

1. Material Reduction: As I mentioned earlier, the high strength means you need less actual metal to do the same job.

2. Maintenance Reduction: In aggressive environments, like chemical processing plants, a standard flange might need replacement every 5 years. A duplex flange can last 20 years or more.

3. Welding Efficiency: While duplex requires skilled welding, its thermal expansion is lower than austenitic steel. This reduces distortion during the joining process, leading to fewer re-works and faster project completion. At Centerway Steel, we focus on helping you calculate these long-term savings. We do not just sell a pipe fitting; we provide a solution that protects your budget for the next decade. When you factor in the reduced downtime and longer replacement intervals, the Return on Investment (ROI) for duplex is undeniable.

Wrong material selection leads to catastrophic failure in the field. You cannot afford a shutdown that halts the entire supply chain. Industries like offshore oil, desalination, and chemical processing rely heavily on these flanges. They meet strict ASTM A182 standards and handle harsh saltwater and acidic environments without failing.

I have worked with partners in over 100 countries, and I see duplex stainless steel flanges becoming the standard in sectors that demand zero errors. It is no longer just a niche product; it is a necessity for critical infrastructure. Oil and Gas Exploration: In offshore platforms, equipment is exposed to a "splash zone"—an area constantly wet and dry with saltwater. This is the ultimate test for metal. Duplex flanges resist the pitting caused by chloride ions in seawater. We supply products to major companies like ADNOC and CNOOC because they know our flanges can handle the high pressure of deep-sea extraction. Desalination Plants: Turning seawater into drinking water involves high concentrations of brine. This is extremely corrosive. Standard steel rots quickly here. Duplex 2205 is the industry standard for these high-chloride environments because it resists crevice corrosion far better than Type 316. Chemical Tankers and Processing: If you are transporting acids or volatile chemicals, you need a flange that does not react with the fluid. The high Chromium content (22-25%) and Molybdenum (3-4%) in our duplex products create a passive layer that protects the metal from chemical attack. At Centerway Steel, we ensure all our flanges meet international standards such as:

· ASME B16.5: Pipe Flanges and Flanged Fittings Standards.

· NACE MR0175: For Sulfide Stress Cracking resistance (vital for Sour Service in Oil & Gas). We integrate production, inventory, and sales to ensure that when you need a specific certification, we have the documentation ready. We check every heat number and perform rigorous testing (including ultrasonic and impact testing) so you can install our products with total confidence.

Duplex stainless steel flanges provide superior strength and corrosion resistance while reducing long-term costs. For reliable, high-quality pipeline solutions that fit your budget, Centerway Steel is your trusted partner.