News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

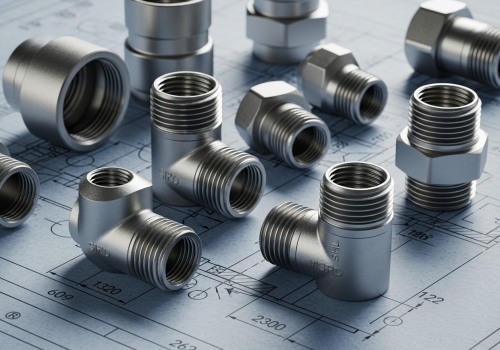

Leaking pipes cost money, stop production, and ruin your reputation. You do not want to explain a critical system failure to your boss because of a single weak fitting that could not handle the load. The stainless steel threaded pipe fittings pressure rating depends on the manufacturing standard (like Class 150 for casting or Class 3000 for forging), the pipe wall thickness, and the operating temperature. Choosing the right rating ensures your system handles the fluid flow without bursting, keeping your project safe and efficient.

Many engineers and purchasing managers overlook the specific pressure details of small fittings until a leak occurs. But I will help you understand these ratings now so you can avoid those expensive mistakes later.

Seeing a number stamped on a fitting does not tell you the whole story. If you ignore temperature and material grade, that "safe" number might actually lead to a dangerous blowout. The pressure rating is determined by the specific standard, such as ASME B16.11 for high-pressure forged fittings or MSS SP-114 for lower-pressure cast fittings. The rating drops as the temperature rises, meaning a fitting rated for 3000 psi at room temperature cannot hold that same pressure at 500°C.

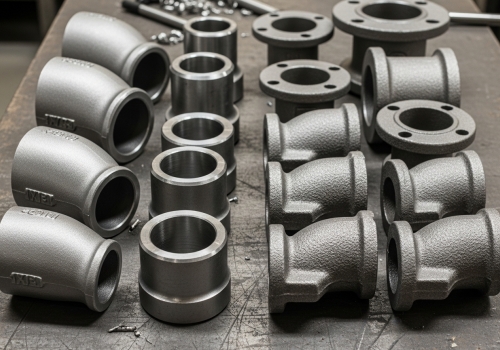

When we talk about the stainless steel threaded pipe fittings pressure rating, we must look at how these fittings are made. There are two main categories that I see most often in my years at Centerway Steel. First, there are cast fittings (usually Class 150). These are great for low-pressure water or air lines. Second, there are forged fittings (Class 2000, 3000, and 6000). These are the heavy-duty workhorses used in oil and gas industries. You need to use critical thinking here. Just because a fitting says "Class 150" does not mean it fails at exactly 150 psi. However, the temperature is the real enemy of pressure. As your system gets hotter, the metal expands and gets slightly weaker. A fitting that is perfectly safe at 20°C might be dangerous at 400°C. Also, the type of thread matters. NPT (National Pipe Taper) threads seal by crushing the metal threads together. If the pressure is too high, it can push the liquid through the spiral leak path of the threads. This is why for very high pressures, we often recommend welding instead of threading. But if you must use threads, you need to select the correct "Class" defined by ASME B16.11. This standard dictates the wall thickness and material strength needed to hold the pressure securely.

Not all fittings are created equal, even if they look the same on the shelf. Mixing up a cast elbow with a forged tee is a recipe for disaster in a high-pressure line. Forged stainless steel fittings, such as those rated Class 3000 or 6000, offer the best resistance for high-pressure lines. Cast fittings are economical but are strictly for low-pressure applications. Matching the fitting class to your pipe schedule (like Schedule 80 or 160) is vital for maintaining system integrity.

In my experience supplying global projects since 1996, I often see confusion between "Pattern" and "Rating." It is crucial to break this down. High-pressure threaded fittings generally follow the ASME B16.11 standard. We classify them into three pressure classes: 2000, 3000, and 6000. These numbers correspond to the wall thickness of the matching pipe. For example, if you are using Schedule 80 pipe, you usually need a Class 3000 fitting to match the pressure capability. If you use a Class 2000 fitting on a Schedule 80 pipe, the fitting becomes the weak point. Conversely, putting a Class 6000 fitting on a thin pipe is a waste of money. Below is a table I created to help you quickly match the fitting class to the pipe schedule for optimal pressure management.

| Fitting Type (ASME B16.11) | Pressure Class | Matches Pipe Schedule | Typical Max Pressure (Ambient) | Best Application |

|---|---|---|---|---|

| Threaded (Forged) | Class 2000 | Schedule 80 / XS | ~2000-3000 psi | Medium pressure hydraulic lines |

| Threaded (Forged) | Class 3000 | Schedule 160 | ~3000-5000 psi | High pressure steam or gas |

| Threaded (Forged) | Class 6000 | XXS (Double Extra Strong) | ~6000+ psi | Extreme pressure chemical injection |

| Cast Fittings (ISO 4144) | Class 150 | Standard / Schedule 40 | ~300 psi (Water/Oil/Gas) | Plumbing, low pressure irrigation |

Using this table helps you visualize the relationship. You cannot just guess. If your project requires a stainless steel threaded pipe fittings pressure rating capable of holding 4000 psi, you must ignore Class 2000 and Class 150 entirely. You have to move straight to Class 3000 or higher to ensure safety.

Rust does not just look bad; it eats away the metal holding your pressure back. Even a high-rated fitting will burst if the material cannot survive the chemical environment inside the pipe. Corrosion thins the walls of the fitting over time, drastically reducing its ability to hold pressure. Choosing High-grade 316 stainless steel over 304 helps maintain the pressure rating in harsh, acidic, or salty environments, ensuring the system lasts for years without unexpected leaks.

We have established that wall thickness (Class) determines the initial pressure rating. But as a purchasing manager, you care about the lifecycle cost. How long will that rating last? This is where material selection becomes a critical part of the pressure calculation. Stainless steel 304 is the standard choice. It is strong and has good pressure ratings. However, if you are pumping saltwater or chemicals, 304 will suffer from pitting corrosion. Pitting creates tiny holes in the threads. Once the threads corrode, the effective wall thickness decreases. A fitting that was rated for 3000 psi might fail at 1000 psi after two years of corrosion. This is why at Centerway Steel, we often recommend 316 or 316L stainless steel for clients in the oil and gas or chemical sectors. It contains molybdenum, which fights corrosion. By stopping the rust, you preserve the original stainless steel threaded pipe fittings pressure rating for the life of the project. You are not just buying a fitting; you are buying insurance against pressure loss. When you ask for a quote, always consider if the medium flowing through the pipe will attack the metal. If the answer is yes, the material grade is just as important as the pressure class.

To ensure safety, always match the pressure class (2000, 3000, 6000) to your pipe schedule and choose the right material grade to maintain that pressure over time.