News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Corrosion failures in pipeline projects usually start with poor welding practices. These failures cause massive financial losses and dangerous downtime for your facility. I will help you solve this problem. Success in welding stainless steel pipe requires controlling heat input to prevent sensitization. You must select the correct low-carbon filler metals and use proper shielding gas like Argon. Advanced processes like TIG for root passes or RMD for thicker walls ensure strong, corrosion-resistant joints.

Many purchasing managers and engineers overlook the specific technical requirements of the welding process. This oversight leads to budget overruns and project delays later on. You need to understand these details to choose the right materials and the right fabrication partner.

Wrong filler metals ruin expensive stainless steel instantly. Your project specifications might be at risk of failing inspection. Let's fix your selection criteria now. Always match the filler metal to the base pipe grade. Use "L" grades (like ER308L) for low-carbon pipes to prevent corrosion. For dissimilar metals, use 309 series fillers. Avoiding high carbon content in the weld pool is the key to longevity.

Selecting the right filler metal is the first step to a successful project. I have seen many projects fail because a welder used a standard 308 filler on a 304L base metal. This raises the carbon content in the joint. High carbon content attracts corrosion. In high-purity industries like food or pharmaceuticals, this is a disaster. You must check the "L" designation. This stands for "Low Carbon." It is also vital to watch out for trace elements in your filler metals. Elements like sulfur or phosphorus can weaken the weld. You want a filler metal that promotes fluidity, like those with higher silicon content (ER309LSi), but keeps harmful impurities low. If you are joining stainless steel to mild steel, you cannot use standard matching fillers. You need the 309 series to handle the dilution. Here is a simple guide to matching your base metals and fillers:

| Base Metal Grade | Recommended Filler Metal | Application Note |

|---|---|---|

| 304 / 304L | ER308L | Standard for general piping. Keeps carbon low. |

| 316 / 316L | ER316L | Essential for acidic or marine environments. |

| 309 / Carbon Steel | ER309L | Used when joining stainless to carbon steel. |

| 321 / 347 | ER347 | stabilized grades for high-temperature service. |

Stainless steel warps and loses rust resistance when overheated. This hidden damage destroys pipeline integrity from the inside out. You can avoid this by managing interpass temperatures. Sensitization occurs when chromium carbides form between 500°C and 800°C, robbing the steel of its protective layer. You must minimize the time the weld spends in this temperature zone. Use low heat input and fast cooling speeds to maintain the pipe's chemical stability.

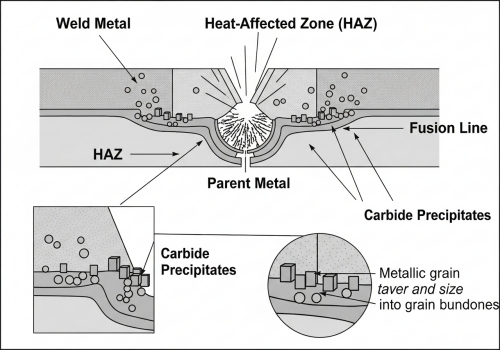

Heat is the enemy of stainless steel. The material relies on a layer of chromium oxide to stay "stainless." If you heat the metal too much or for too long, the carbon draws the chromium away from the grain boundaries. This creates chromium carbides. We call this sensitization. The steel will rust in these areas as if it were plain iron. You have three main ways to fight this. First, use the low-carbon materials we discussed above. Second, control your interpass temperature. I recommend keeping the steel below 150°C (300°F) before starting the next weld pass. This allows the heat to dissipate. Third, use faster travel speeds. The less time the arc stays in one spot, the better. Modern technology helps us here. Old transformer welding machines were slow and hot. New inverter TIG machines allow for high-speed pulsing (up to 500 pulses per second). This focuses the arc. It melts the metal quickly without soaking the surrounding pipe in heat. This reduces the heat-affected zone (HAZ). If you are supervising a welding stainless steel pipe project, check that your fabricators monitor temperature strictly.

TIG is slow, but MIG often lacks quality in critical applications. Choosing the wrong process hurts your schedule or your quality standards. Here is the right balance for your needs. TIG is the gold standard for high-purity, small-diameter pipes due to its precision. For larger, thicker pipes (Schedule 40+), modified short-circuit MIG (like RMD) offers higher speed without sacrificing root quality. Your choice depends on the pipe diameter and application requirements. We need to balance productivity with quality. For small tubes, specifically those under 6 inches in diameter or with thin walls (Schedule 10), Gas Tungsten Arc Welding (TIG) is the best choice. It is clean and precise. You can often fuse the metal without adding filler (autogenous welding), which keeps the chemistry pure. However, TIG is slow. It travels at about 3 to 5 inches per minute. For larger projects, like the oil and gas pipelines I often supply, speed matters. This is where modified MIG processes like Regulated Metal Deposition (RMD) shine. RMD controls the short circuit to create a calm puddle. It allows welders to work much faster—up to 12 inches per minute. That is a huge productivity gain. Shielding gas is also part of this decision. TIG requires pure Argon. MIG needs a mix. But be careful. Standard MIG mixes with too much CO2 will add carbon to your weld. You need specialized mixes with 2-3% CO2 or Oxygen, just enough to stabilize the arc but not enough to ruin the corrosion resistance.

| Feature | TIG (GTAW) | Modified MIG (RMD) |

|---|---|---|

| Speed | Slow (3-5 ipm) | Fast (6-12 ipm) |

| Quality | Excellent (High Purity) | Very Good (Industrial) |

| Heat Input | Moderate to High (if slow) | Low (Controlled short circuit) |

| Best For | Thin wall, Food/Pharma | Thick wall, Oil & Gas, Structural |

Choosing the right process for welding stainless steel pipe ensures you meet deadlines without facing rejection during X-ray inspection.

You ensure project success by selecting low-carbon fillers, controlling heat input, and choosing the right welding process for your pipe size. At Centerway Steel, we understand these technical challenges. As a one-stop supplier since 1996, we provide high-quality stainless steel pipe that meets the strictest welding and material standards, helping you build with confidence.