News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

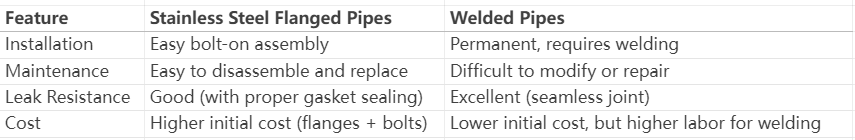

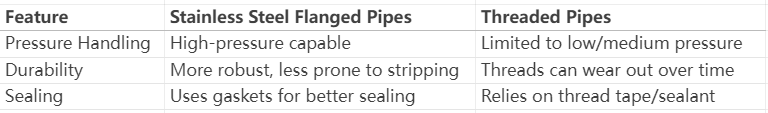

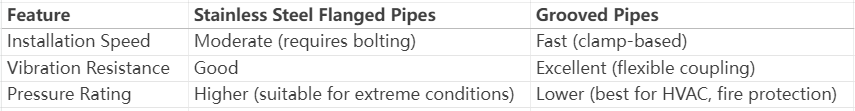

When designing a piping system, choosing the right connection method is crucial for performance, durability, and maintenance. Stainless steel flanged pipes are a popular choice, but how do they compare to alternatives like welded, threaded, or grooved connections? This guide explores the pros and cons of each method to help you decide which is best for your application.

Stainless steel flanged pipes consist of pipes with flanges welded or screwed at the ends, allowing for easy bolted connections. They are widely used in industries like oil & gas, chemical processing, and water treatment due to their:

· High strength and leak resistance

· Easy assembly and disassembly for maintenance

· Compatibility with high-pressure and high-temperature systems

Compared to other connection types, stainless steel flanged pipes offer a balance of durability and flexibility.

✅ Best for: Systems requiring frequent maintenance or modifications (e.g., industrial plants).

✅ Best for: High-pressure or corrosive environments where threaded connections may fail.

✅ Best for: Heavy-duty applications where pressure and temperature resistance are critical.

Stainless steel flanged pipes are ideal when:

✔ Frequent maintenance or inspection is needed (e.g., chemical processing plants).

✔ High-pressure or high-temperature conditions exist (e.g., oil refineries).

✔ Interchangeability is important (standardized flange sizes allow easy replacements).

However, welded or grooved connections may be better for permanent, low-maintenance systems.

The best choice depends on your project’s needs:

· Choose stainless steel flanged pipes for durability, easy maintenance, and high-pressure performance.

· Opt for welded pipes for permanent, leak-proof systems.

· Use threaded or grooved connections for low-cost, quick-installation scenarios.

By understanding these differences, you can select the most efficient and cost-effective piping solution.

Whether you need stainless steel flanged pipes or alternative connections, always consider factors like pressure, temperature, maintenance, and budget. For industries requiring reliability and adaptability, flanged systems remain a top choice.

Need help selecting the right piping solution? Contact our experts today for tailored advice!