News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Super austenitic stainless steel is a high-performance alloy designed to withstand extreme corrosive environments where standard stainless steels fail. With enhanced levels of chromium, molybdenum, and nitrogen, these steels offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC).

In this article, we’ll explore the properties of super austenitic stainless steel, its key advantages, and its most common industrial applications.

The exceptional performance of super austenitic stainless steels comes from their unique chemical composition and microstructure. Here are the key characteristics:

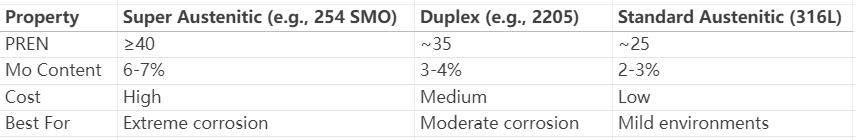

· Contains high molybdenum (6-7%) and nitrogen (0.2-0.5%), significantly improving resistance to chlorides, acids, and seawater.

· Outperforms standard 316L and 904L stainless steels in aggressive environments.

· Higher tensile and yield strength compared to conventional austenitic grades.

· Maintains ductility and toughness even at cryogenic temperatures.

· Measured by the Pitting Resistance Equivalent Number (PREN)—often exceeding 40 (compared to ~25 for 316L).

· Ideal for offshore, chemical processing, and desalination plants.

· Requires controlled welding techniques (e.g., TIG, laser welding) to prevent carbide precipitation.

· Post-weld heat treatment may be needed for critical applications.

Due to its superior corrosion resistance and durability, super austenitic stainless steel is widely used in:

· Reactors, heat exchangers, and piping systems handling sulfuric acid, hydrochloric acid, and chlorides.

· Seawater desalination plants, shipbuilding, and subsea equipment due to resistance to saltwater corrosion.

· Downhole tubing, flow lines, and LNG processing where sour gas (H₂S) resistance is critical.

· Hygienic environments requiring high purity and resistance to sterilization chemicals.

· Flue gas desulfurization (FGD) systems and nuclear waste storage due to long-term stability.

Super austenitic stainless steel is the go-to material for industries requiring unmatched corrosion resistance in harsh conditions. Its high molybdenum and nitrogen content make it ideal for chemical processing, marine applications, and oil & gas infrastructure.

If your project involves aggressive media or long-term durability, investing in super austenitic stainless steels can reduce maintenance costs and extend equipment lifespan.

Would you like recommendations on specific grades (e.g., AL-6XN, 254 SMO) for your application? Let us know in the comments!