News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

In industrial piping systems, SS flanges (stainless steel flanges) play a critical role in connecting valves, pumps, and other equipment. When operating under high temperature conditions, the choice of flange becomes even more important. Selecting the wrong material or type can lead to failure, leaks, or even dangerous accidents.

This guide will walk you through everything you need to know about using SS flanges in high-temperature environments—covering material selection, design considerations, common standards, and best practices.

Stainless steel is known for its excellent resistance to heat, corrosion, and pressure. Compared to carbon steel or cast iron, an SS flange maintains structural integrity at elevated temperatures, making it ideal for industries like:

· Petrochemical

· Power generation

· Refinery

· Steam processing

· Chemical manufacturing

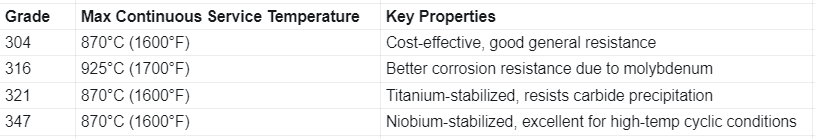

Stainless steels such as 304, 316, 321, and 347 are commonly used, but not all are suitable for every high-temperature application. Material choice should be based on both temperature and chemical compatibility.

Here’s a breakdown of popular stainless steel grades and their maximum service temperatures:

Note: Always confirm actual temperature limits with manufacturers, as factors like pressure and thermal cycling can affect performance.

High temperature environments place extra mechanical and thermal stress on flanges. When selecting or designing an SS flange, consider the following:

· Flange Type: Weld neck flanges are best for high-temp and high-pressure applications due to their strength and stability.

· Gasket Material: Choose gaskets compatible with both temperature and media (e.g., graphite or spiral wound gaskets).

· Bolt Material: Bolts and nuts should also withstand high temperatures—often alloy steel or stainless steel grades.

· Thermal Expansion: Ensure that piping design accounts for thermal expansion to prevent flange misalignment or leakage.

For high-temperature use, it's essential that SS flanges comply with industry standards to ensure safety and performance. Key standards include:

· ASME B16.5 (for flanges up to 24 inches in size)

· ASME B16.47 (for larger diameters)

· EN 1092-1 (European standard)

· DIN series (German/European applications)

Standards also provide pressure-temperature ratings (e.g., Class 150, 300, 600), which guide suitable flange selection based on system pressure and heat.

· Steam pipelines

· Heat exchangers

· Reactor vessels

· Furnace piping

· High-temperature exhaust systems

In these systems, the long-term durability and safety of SS flanges are essential.

1. Routine inspection for signs of corrosion or creep deformation

2. Torque management to maintain correct bolt tension despite thermal cycling

3. Proper installation using compatible gasket and bolt materials

4. Avoid over-tightening, which can damage the flange face at high heat

5. Use of thermal insulation, where applicable, to reduce heat stress

Using the right SS flange in high-temperature applications is not just about withstanding heat—it’s about ensuring long-term safety, reliability, and efficiency. By choosing the proper stainless steel grade, ensuring compliance with industry standards, and designing thoughtfully, you can avoid costly downtime and performance issues.

Looking for high-quality SS flanges that perform under pressure and heat? Contact us today to learn more about our product range and engineering support for demanding environments.