News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Corrosion eats your profits and causes dangerous leaks in your pipelines. Are you tired of replacing pipes in your seawater or chemical projects too often? S32750 stainless steel, also known as Super Duplex 2507, is a ferritic-austenitic alloy designed for extreme conditions. It offers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking due to its high chromium, molybdenum, and nitrogen content, making it ideal for marine and chemical industries.

We know that finding the right material is hard, so let us break down exactly why this specific grade saves you money and time.

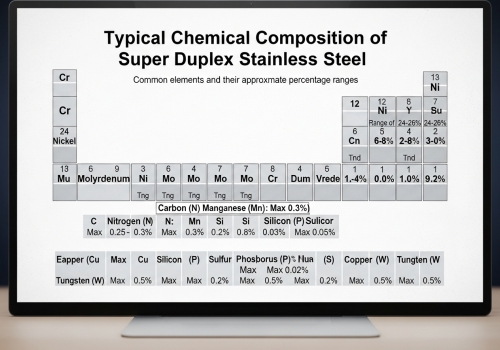

You need to know the ingredients to trust the product quality. Without the right chemical mix, your project faces a high risk of failure in harsh waters. The chemical composition of s32750 stainless steel includes 24-26% Chromium, 6-8% Nickel, and 3-5% Molybdenum. This precise balance gives the alloy its "Super Duplex" status, providing superior strength and corrosion resistance compared to standard duplex or austenitic steels.

I have seen many data sheets in my time at Centerway Steel, and the chemistry of this grade is truly impressive. It is not just about the numbers; it is about what those numbers do for you. To understand why s32750 stainless steel performs so well, we must look at the specific roles of its main elements. Here is the standard composition table based on ASTM standards:

| Element | Content (%) | Role in the Alloy |

|---|---|---|

| Chromium (Cr) | 24.0 – 26.0 | Provides the main protection against rust and oxidation. |

| Nickel (Ni) | 6.0 – 8.0 | Stabilizes the structure and improves toughness. |

| Molybdenum (Mo) | 3.0 – 5.0 | drastically increases resistance to pitting corrosion. |

| Nitrogen (N) | 0.24 – 0.32 | Increases strength and improves pitting resistance. |

| Copper (Cu) | 0.50 max | Helps resistance in acidic environments. |

| Iron (Fe) | Balance | The base metal. |

Why does this matter? In the oil and gas industry, a PREN above 40 is the gold standard for seawater service. The high Nitrogen content is also special. It allows the material to have better structural stability and higher strength without making it too brittle. This balance means we can produce pipes that last for decades, even when submerged in aggressive salt water.

High pressure breaks weak pipes and stops production instantly. You cannot afford leaks or downtime when managing a high-stakes EPC project. S32750 boasts a yield strength roughly twice that of standard austenitic stainless steels like 304 or 316. It combines high thermal conductivity with low thermal expansion, allowing it to handle extreme physical stress and temperature fluctuations without deforming or cracking.

When we supply pipeline products to global partners like ADNOC or Shell, mechanical strength is their top concern. They want to know if the pipe can handle the pressure. The physical properties of S32750 are far superior to standard grades. This high strength allows you to use thinner walls for your pipes. Think about the cost savings. If you use a thinner wall pipe that handles the same pressure, the total weight of the project goes down. Less weight means lower shipping costs and lower welding consumables costs. Here are the critical physical and mechanical properties:

| Property | Metric Value | Imperial Value | Significance |

|---|---|---|---|

| Density | 7.8 g/cm³ | 0.281 lb/in³ | Similar to carbon steel, easy to calculate weight. |

| Melting Point | 1350°C | 2460°F | Withstands high heat environments. |

| Yield Strength | ≥ 550 MPa | ≥ 80 ksi | Twice as strong as 316L Stainless. |

| Tensile Strength | ≥ 800 MPa | ≥ 116 ksi | Resists breaking under tension. |

| Elongation | ≥ 15% | ≥ 15% | Maintains ductility despite high strength. |

Choosing the wrong material for the wrong place causes disasters and safety hazards. Do not guess; we know exactly where this alloy performs best. This alloy is essential for oil and gas exploration, seawater desalination plants, and chemical processing. It is specifically used for subsea pipelines, heat exchangers, and high-pressure vessels where chloride-rich environments destroy lesser metals quickly.

At Centerway Steel, we have integrated this material into massive projects across more than 100 countries. We see s32750 stainless steel being used where failure is not an option. It is not just a pipe; it is a safety barrier. We recommend this grade for the following specific sectors:

This is our biggest market. The material resists sour gas and high-chloride environments.

· Separators and heat exchangers: It resists the corrosive mix of oil, gas, and water.

Desalination plants are very aggressive environments. High chloride levels attack standard steel. S32750 resists crevice corrosion, which often happens in tight spaces like flange connections.

The alloy works well against organic acids.

· Cargo tanks: For ships carrying hazardous chemicals.

· Absorber towers: Used in flue gas cleaning.

In geothermal and coastal power plants, the cooling water is often brackish or salty. S32750 pipes resist erosion-corrosion caused by the high-speed flow of this water. Common Product Forms We Supply:

· Seamless and Welded Pipes: For transport lines.

· Flanges and Fittings: Critical for leak-proof connections.

· Plates and Bars: For custom equipment fabrication. By choosing this material, you ensure the longevity of your equipment. It minimizes maintenance shutdowns, which keeps your end-users happy and your project on budget.

S32750 is the top choice for high-strength, corrosive environments like marine and chemical sectors. If you want to ensure your project's success with reliable quality, Centerway Steel is ready to help. We supply premium s32750 stainless steel pipe and fittings to meet your exact specifications. Contact us today for a quote!