News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Leaking joints and seized threads can ruin your pipeline project instantly. Are you tired of stainless steel fittings galling during assembly? I have the proven solution for you right here. To learn how to seal stainless steel pipe threads, you must use a combination of nickel-grade PTFE tape and a quality thread sealing compound. This dual method prevents galling, lubricates the joint, and fills microscopic voids to ensure a high-pressure, leak-free seal every time.

Many people struggle with this specific material. Let me explain why it happens and the best way to fix it.

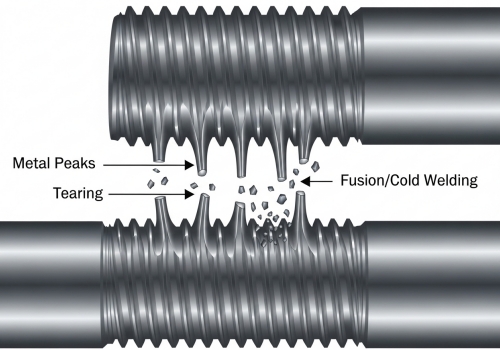

You treat stainless like brass, but it seizes up. This costs money and time. Why does this strong metal fail during installation? The main reason is a phenomenon called "galling," or cold welding. When threads rub against each other, the protective oxide layer breaks. This causes the metals to fuse. Sealing stainless steel threaded connections requires heavy lubrication to stop this friction.

At Centerway Steel, we have supplied pipelines for oil and gas projects since 1996. We have seen many site engineers confused by damaged threads. They ask me, "Why did this happen? I barely tightened it." The answer lies in the material properties. Stainless steel is distinctively hard. When you assemble a stainless nipple into a fitting, the friction creates heat. Unlike brass, which is softer and self-lubricating to a degree, stainless steel threads are "sticky." When the surfaces rub under the pressure of the wrench, the thin chromium oxide layer—which prevents rust—gets scraped off. Without this layer, the high points of the raw metal touch. They instantly weld together. This is cold welding. If you try to reverse the wrench, the threads tear. The fitting is ruined. To prevent this, you need a barrier. You need something that separates the two metal surfaces completely.

Comparison of Thread Behaviors

| Feature | Brass/Bronze | Stainless Steel |

|---|---|---|

| Hardness | Soft to Medium | Very Hard |

| Friction Heat | Low | High |

| Galling Risk | Low | Very High |

| Sealing Need | Standard Tape often works | Specialized Nickel Tape + Compound |

In my experience serving global EPC companies, skipping the right preparation for stainless steel is the number one cause of project delays in the installation phase. You must respect the hardness of the material.

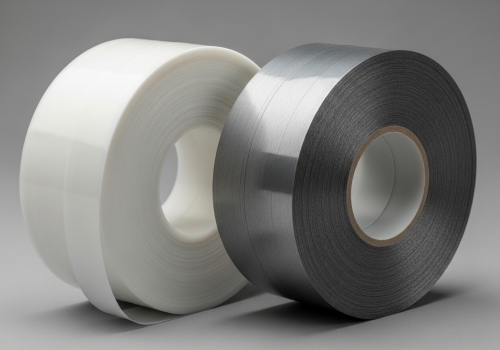

Using standard white tape often leads to failure. You need the right tools for the job. What exactly should be in your toolbox? You need high-density, nickel-pigmented PTFE tape (often gray) and a non-seizing pipe thread compound. The nickel tape prevents galling, while the compound acts as a secondary seal. This is the best method for how to seal stainless steel pipe threads.

I always tell my customers that relying on just one method is risky for stainless steel. We recommend a dual-barrier system. This is often called the "Belt and Suspenders" method. You use the tape (the belt) and the paste (the suspenders).

1. Gray Stainless Steel PTFE Tape You might have white tape in your toolbox. Throw it away if you are working with stainless steel. You need Gray PTFE (Polytetrafluoroethylene) tape.

· Density: This tape is thicker and denser. It does not shred easily when you tighten the sharp stainless threads.

2. Gray Magic Pipe Thread Compound This is a soft-settling, non-hardening paste.

· Lubrication: Its primary job is to make the assembly smooth. It reduces the friction heat that causes galling.

· Sealing: The tape covers the major gaps, but the compound flows into the tiny imperfections in the thread root. Material Checklist for Purchasing Managers

| Item | Specification | Purpose |

|---|---|---|

| Tape | Nickel-infused PTFE (Gray) | Anti-galling barrier |

| Compound | Industrial Grade, Non-seizing | Lubrication and micro-sealing |

| Cleaner | Degreasing solvent | Removes oil/dirt before application |

| Tools | Strap wrench or pipe wrench | Tightening without deformation |

If you are sourcing for a large project, ensure your installation team has these specific consumables. Using cheap substitutes will cost more in damaged valves and fittings later.

Knowing the tools is not enough. You must apply them correctly. One wrong move can damage the thread permanently. Clean the threads thoroughly first. Wrap the gray PTFE tape 3-4 times in the direction of the thread. Apply a layer of pipe dope over the tape. Tighten the fitting by hand, then finish with a wrench.

I have guided partners in over 100 countries on installation. The process is the same whether you are in a refinery in the Middle East or a water plant in Europe. Here is the detailed breakdown of how to seal stainless steel pipe threads effectively.

Step 1: Cleaning is Crucial New pipes from the factory often have cutting oil or metal shavings on them.

· Use a degreaser.

· Wipe the male and female threads clean.

· Dirt prevents the tape from sticking and can cause leaks.

Step 2: Apply the Nickel Tape

· Start at the second thread from the end. Leaving the first thread bare helps the fitting engage easily.

· Direction matters: Hold the pipe in your left hand. Lay the tape over the top. Roll the tape away from you (clockwise). This ensures the tape tightens down when you screw the pipe in. If you wrap it backward, the tape will unravel.

· Tension: Pull the tape tight. It should sink into the grooves of the threads.

· Wraps: For standard 3.5 to 4.0 mil tape, use 3 full wraps. If the tape is thinner, use 4 or 5 wraps.

Step 3: Apply the Compound

· Stir the compound well.

· Brush a liberal amount of the Gray Magic compound over the tape you just applied.

· Do not rely on the paste alone. The combination is key.

Step 4: Tightening

· Hand-tighten the fitting first. You should feel smooth resistance.

· Use a wrench for the final turns.

· Warning: Do not over-tighten. Stainless steel has a tapered thread (NPT). If you force it too far, you can crack the female fitting (especially with valves) or induce galling despite the tape.

Step 5: Inspection Look for the compound squeezing out slightly.

This indicates a full fill. Wipe away the excess for a professional look. By following this protocol, Centerway Steel ensures that our high-quality products perform perfectly in your system. We want to see a win-win cooperation, and that means zero leaks on your site.

To prevent leaks, clean the threads, apply three wraps of gray nickel PTFE tape, and cover it with a non-seizing thread compound before tightening the joint.