News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

You need high-quality stainless steel tubing for your critical systems, but navigating standards is confusing. A wrong choice leads to system failure and lost money. Let me simplify this for you. ASTM A269 tubing specifications cover seamless and welded austenitic stainless steel tubing for general service. This standard ensures corrosion resistance and low- or high-temperature performance. It defines strict requirements for chemical composition, mechanical properties, and dimensional tolerances, making it vital for chemical, food, and industrial applications.

I know the pressure of finding the right materials for a big project. I will break down everything you need to know to make the right buying decision.

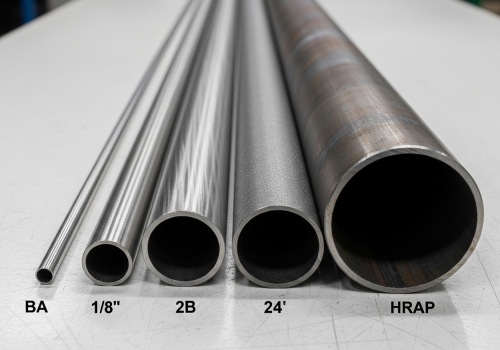

Many buyers confuse general tubing with specific pressure grades. You need to know exactly what you are paying for to avoid audit issues later. This standard covers grades like 304 and 316 for general corrosion-resisting service. It focuses on wall thickness, outer diameter, and surface finish rather than just high-pressure ratings found in pipe standards.

I have spent years at Centerway Steel helping clients understand what they are buying. ASTM A269 is one of the most common requests I see. It is a standard issued by ASTM International. It covers both seamless and welded austenitic stainless steel tubing. The main focus here is general service. This means it is great for corrosion resistance and works well in both low and high temperatures. The standard is not just about the type of steel. It is about how the tube is made and tested. It includes common grades like TP304, TP304L, TP316, and TP316L. These are the workhorses of the industry. I often see this used in instrumentation and hydraulic lines. The standard ensures the tubes are clean and strong. It requires specific manufacturing practices. For example, the tubes must be heat treated. This gives them a uniform structure. This is vital for your project because it means the tube will not crack under normal stress. Also, this standard is a "living document." It changes as technology gets better. We keep up with these changes so you do not have to. When you order to this spec, you get assurances on yield strength and hardness. You also get assurances on how the tube looks. It must be free of defects. This is why I recommend it for projects where visual inspection is part of the quality control process.

Precision is everything in your design drawings. If the physical tube doesn't match your CAD model, installation stops and costs rise. The technical details define the limits for chemical content, tensile strength, and hardness. ASTM A269 tubing specifications also dictate strict tolerances for diameter and wall thickness to ensure a perfect fit in compression fittings.

You need to look closely at the numbers. The ASTM A269 tubing specifications provide a clear rulebook for what makes a good tube. First, let's talk about chemistry. The steel must have the right amount of Chromium and Nickel. For 316 grade, it also needs Molybdenum. This is what stops rust in salty or acidic places. If the chemistry is off, the tube fails. Next is the mechanical side. The standard sets a minimum tensile strength and yield strength. It also sets a maximum hardness. We test this to make sure the tube can bend without breaking. This is important for your installation teams. They need materials that are easy to work with but strong enough to last. Then there are dimensions. This is where many suppliers fail. The standard has strict rules for the Outside Diameter (OD) and wall thickness. For small tubes, the tolerance is very tight. A tube that is too big will not fit in a connector. A tube with a thin wall will burst. We use laser tools to check this. Here is a simple table to show the chemical limits for the most common grades we supply:

| Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Carbon (Max %) |

|---|---|---|---|---|

| TP304 | 18.0 - 20.0 | 8.0 - 10.5 | N/A | 0.08 |

| TP304L | 18.0 - 20.0 | 8.0 - 12.0 | N/A | 0.035 |

| TP316 | 16.0 - 18.0 | 10.0 - 14.0 | 2.0 - 3.0 | 0.08 |

| TP316L | 16.0 - 18.0 | 10.0 - 14.0 | 2.0 - 3.0 | 0.035 |

You might see A213 or A312 on a requisition list. Choosing the wrong one is a common mistake that delays projects and upsets engineers. A269 is for general service tubing, while A213 is specifically for boilers and heat exchangers. A312 covers pipes, not tubes. Knowing the difference ensures you buy the correct product for the specific pressure and temperature application.

I get this question all the time from procurement managers. It is easy to mix these up. ASTM A312 is for pipe, not tubing. In our industry, pipe is measured by "Nominal Pipe Size" (NPS). This refers roughly to the inside diameter for flow. But ASTM A269 is for tubing. Tubing is measured by the exact Outside Diameter (OD). This is crucial. If you order A312 pipe for a compression fitting designed for A269 tube, it will not fit. The sizes are different. Then there is ASTM A213. This is very similar to A269. The main difference is the application. A213 is specifically for boilers and heat exchangers. It has stricter rules for minimum wall thickness. A269 usually deals with "nominal" or average wall thickness. If your engineers are designing a superheater for a power plant, they probably want A213. But for general instrumentation lines, A269 is the standard choice. There is also A249. This is for welded boiler tubes. A269 allows both seamless and welded types. If you need to save money, welded A269 is a great option. It is cheaper than seamless but still very strong. I always tell my clients to check their spec sheets. Over-specifying costs you money. Under-specifying risks safety. A269 is often the sweet spot for general industrial needs. It is versatile and readily available in our stock.

You want to know if this material works for your specific end-user. Whether it is oil, gas, or food, the application dictates the material choice. This specification is the industry standard for chemical processing, hydraulic lines, and sanitary systems. ASTM A269 tubing specifications guarantee that the material is clean, durable, and resistant to harsh environments like saltwater or acidic food products.

The versatility of this tubing is amazing. I have shipped these tubes to over 100 countries for very different jobs. In the Oil and Gas sector, we see A269 used for hydraulic control lines. These are the small lines that control valves on big rigs. They must not leak. The environment is harsh, often with salt spray. The 316 grade under A269 is perfect here because of the Molybdenum content. Then look at the Food and Beverage industry. Cleanliness is the law here. The surface finish requirements of A269 help. The tubes are smooth. Bacteria have nowhere to hide. We supply these for milk transfer lines and brewery systems. The tubing withstands the harsh cleaning chemicals used to sanitize the lines. Chemical processing is another huge market. Acids and aggressive fluids eat normal steel. Austenitic stainless steel resists this attack. I also see it in the automotive world and HVAC systems. They use it for heat exchangers. The tube walls are thin enough to transfer heat but strong enough to hold pressure. Pharmaceuticals also use this. But they often ask for an even higher surface finish, sometimes called "electropolished." While A270 is the sanitary standard, A269 is often the base material. We understand these needs. Whether it is a high-pressure line on an oil platform or a clean line in a pill factory, this standard covers it. It is the backbone of modern industry infrastructure.

Understanding ASTM A269 tubing specifications saves you time and money. It ensures you get safe, durable tubing for general services. At Centerway Steel, we are ready to supply your needs.