News

Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

When designing or installing a piping system, one of the most common fittings is the stainless steel 90 degree elbow. This component changes the direction of flow by 90 degrees, making it essential for systems in industries such as oil and gas, chemical processing, food and beverage, and water treatment. While the shape and function may look simple, the manufacturing process of a stainless steel 90 degree elbow plays a critical role in its strength, durability, and long-term performance.

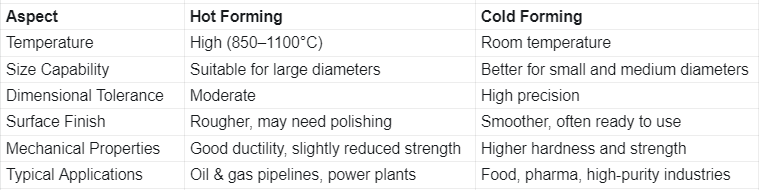

This article explains the two main manufacturing methods—hot forming and cold forming—to help engineers, buyers, and technicians understand the differences and make informed decisions.

Hot forming, also called hot mandrel bending or hot pushing, involves heating a stainless steel pipe segment to high temperatures (usually 850–1100°C) and then shaping it over a die or mandrel.

· Material Flexibility: Heat reduces material hardness, making it easier to form without cracking.

· Larger Sizes Possible: Hot forming is ideal for manufacturing large-diameter elbows.

· Grain Structure: At high temperatures, the stainless steel grain structure changes, which may slightly reduce mechanical strength but ensures excellent ductility.

· Surface Finish: Often requires additional machining or polishing to improve surface quality.

Hot forming is commonly used for industrial-grade stainless steel 90 degree elbows in pipelines that handle high pressure and temperature.

Cold forming is a process where the elbow is shaped at room temperature, typically using hydraulic presses and dies. Unlike hot forming, it does not involve heating the material to high temperatures.

· Dimensional Accuracy: Cold forming provides more precise dimensions and tighter tolerances.

· Surface Quality: Produces a smoother surface finish, often eliminating the need for extra polishing.

· Material Properties: Cold working can increase hardness and strength due to strain hardening.

· Size Limitation: Generally used for small to medium-diameter elbows.

Cold forming is preferred when high dimensional precision and surface finish are critical, such as in sanitary or food-grade piping systems.

When selecting a stainless steel 90 degree elbow, the choice between hot forming and cold forming depends on several factors:

1. Pipeline Size: Large-diameter pipelines usually require hot-formed elbows.

2. Operating Conditions: For high-pressure, high-temperature service, hot-formed elbows are preferred.

3. Surface & Cleanliness Requirements: For hygienic applications (e.g., food or pharma), cold-formed elbows offer smoother surfaces.

4. Budget Considerations: Hot forming is generally more cost-effective for heavy-duty applications, while cold forming may cost more due to precision tooling.

Both hot forming and cold forming methods have unique advantages in producing stainless steel 90 degree elbows. Hot forming is best for heavy-duty, large-scale industrial use, while cold forming excels in applications requiring precision, surface finish, and smaller sizes. By understanding these processes, engineers and buyers can select the most suitable elbow for their specific pipeline system, ensuring long-term reliability and efficiency.