News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

You invest in stainless steel for its durability, but seeing orange spots on your expensive piping can be a nightmare. Ignoring these signs leads to costly failures, but prevention is simple. To understand how to prevent stainless steel from rusting, you must primarily focus on maintaining its passive chromium oxide layer. Regular cleaning with mild detergents, avoiding chloride-rich environments, preventing cross-contamination from carbon steel tools, and performing timely passivation on weld sites are the most effective strategies for ensuring long-term durability.

Many people believe that "stainless" means it will never corrode, but that is a dangerous misconception. While this material is incredibly tough, it is not magic. Let me explain why it fails so you can avoid the headache of replacing your equipment too soon.

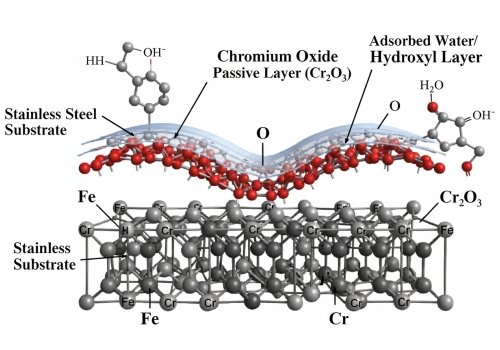

We choose this material specifically for its resistance, yet it still corrodes under certain conditions. Why does this happen to our high-quality materials? It all comes down to the chromium content reacting with oxygen to form a thin, invisible passive film. When this shield is compromised by chemicals or physical damage faster than it can repair itself, corrosion occurs.

To truly master how to prevent stainless steel from rusting, we first need to understand the science behind it. Stainless steel contains iron, chromium, and other elements. The "magic" ingredient is chromium. When exposed to oxygen in the air, chromium forms a very thin layer of chromium oxide on the surface. We call this the "passive layer." It is this layer that seals the iron inside and prevents it from rusting. However, rust is also an oxide layer, specifically iron oxide. The difference is that iron oxide is flaky and porous. It falls off, exposing more iron to the air, which leads to more rust. The chromium oxide layer is different because it is self-healing. If you scratch the surface, the chromium reacts with oxygen and repairs the seal. But, if the environment is too harsh—full of chlorides like salt water, or if the oxygen supply is cut off—this layer breaks down. At Centerway Steel, we often see that customers who do not understand this mechanism choose the wrong grade of steel for their environment, leading to early failure. Understanding that stainless steel "stains less" rather than "stains never" is the first step in effective project management.

Identifying the enemy is half the battle when managing a construction site. You need to know exactly what specific elements are attacking your pipes. The most common culprits are chlorides (found in salt), mechanical abrasion, low oxygen environments, and high temperatures. These factors aggressively break down the protective layer and prevent it from reforming.

In my experience supplying pipes to global EPC companies, I have noticed that environmental factors are the biggest oversight. It is not just about the quality of the steel; it is about where you put it. For example, chlorides are the arch-nemesis of the passive layer. They are found in sea salt, industrial cleaners, and even tap water. They eat through the chromium oxide and cause "pitting," which are tiny, deep holes. Another major issue is mechanical damage. If a pipe is gouged during installation, moisture can get trapped in the crevice. This creates a low-oxygen environment. Remember, the passive layer needs oxygen to heal. Without it, the layer collapses, and rust begins. Below, I have created a table to help you identify the risks on your specific job site.

| Risk Factor | Description | Prevention Tip |

|---|---|---|

| Chlorides | Salt from seawater or cleaning agents attacks the passive layer. | Use Grade 316 steel and avoid chloride-based cleaners. |

| Iron Contamination | Residue from carbon steel tools transfers to stainless surfaces. | Never use steel wool; keep tools separate. |

| High Temperatures | Welding causes heat tint, depleting chromium in that area. | Pickling and passivation are required after welding. |

| Galvanic Corrosion | Contact between dissimilar metals in an electrolyte. | Use insulating washers or gaskets between different metals. |

Now that we know the causes, let us look at the practical solutions for your site. Good maintenance can extend the life of your equipment by decades. Implement a regular cleaning schedule using warm water and mild soap. Crucially, avoid steel wool and separate carbon steel tools to prevent free iron contamination, which is a leading cause of surface rust.

This is the most critical section for your maintenance team. If you want to know how to prevent stainless steel from rusting, you must establish a strict cleaning routine. For most environments, a simple wash with warm water and a mild detergent (like dish soap) is enough. You should use a soft cloth or a sponge. This removes dirt and grime that can trap moisture and corrosive agents against the metal surface. The biggest mistake I see in the field is the use of abrasive tools. Never, under any circumstances, use ordinary steel wool or wire brushes made of carbon steel on your stainless pipes. These tools leave behind tiny particles of iron. These particles will rust immediately and stain the stainless steel beneath them. This is called "free iron contamination." If you need to scrub hard, use a nylon scourer or a brush with stainless steel bristles. Also, if you are storing pipes before installation, do not stack stainless steel directly on top of carbon steel beams. Always use wooden spacers or rubber mats to keep them electrically isolated.

Seeing orange spots does not always mean the equipment is ruined. You can often restore it if you catch the problem early enough. For light rust, a paste of baking soda and water works well. For deeper corrosion, pickling pastes containing mild acids or professional electropolishing may be required to completely restore the passivation layer.

If preventative measures have failed, do not panic. You can often fix the issue without replacing the entire pipe section. For minor surface rust, I recommend a simple home remedy that works on industrial sites too: baking soda. Mix baking soda with water to make a thick paste. Apply it to the rusted area and let it sit for about an hour. Then, scrub it gently with a plastic pad. This is non-abrasive and usually removes the stain. For more severe rust, or discoloration caused by welding heat, you will need a chemical approach. Products containing oxalic acid or specific "pickling pastes" are very effective. These chemicals strip away the rust and a thin layer of the metal, forcing a new, strong passive layer to form. However, always check the Material Safety Data Sheet (MSDS) before using these chemicals, as they can be hazardous. In extreme cases, or for complex shapes, we recommend electropolishing. This process uses an electric current to remove surface imperfections and iron, leaving the steel incredibly smooth and resistant to future corrosion. However, if the rust has eaten deep into the structural integrity of the pipe, replacement is the only safe option.

Stainless steel requires oxygen and cleanliness to maintain its self-healing layer. By avoiding chlorides, preventing iron contamination, and cleaning regularly, you can ensure your pipelines last a lifetime.

If you are looking for a partner who understands the intricacies of material science and project management, look no further. At Centerway Steel, we do not just sell pipes; we provide integrated solutions. Since 1996, we have supplied high-quality stainless steel pipe, fittings, and valves to Fortune 500 companies globally. Whether you need large diameter, heavy thickness, or high-precision pipes, our ISO-certified products are ready to meet your project's demands. Contact us today to ensure your next project is built to last.