News

Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

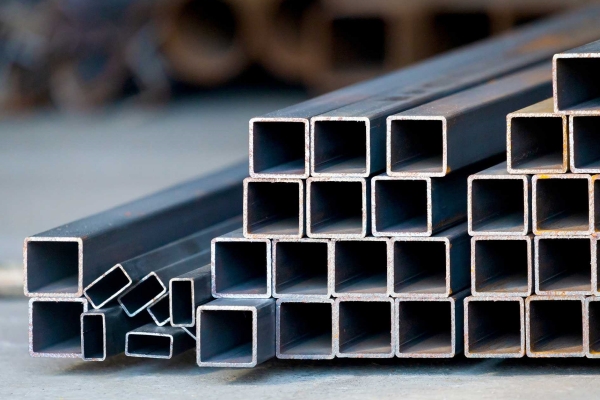

When it comes to structural and architectural applications, stainless square tube is a top choice due to its exceptional durability, corrosion resistance, and sleek modern appearance. Whether used in construction, industrial frameworks, or high-end furniture, understanding the load-bearing capacity of a stainless square tube is crucial for ensuring safety, stability, and long-term performance.

In this guide, we’ll explore the key factors that affect load support, best applications, and how to calculate the weight-bearing capacity of a stainless square tube for your specific needs.

Several critical factors determine how much weight a stainless square tube can support:

Stainless steel tubes come in different grades, with 304 and 316 being the most common:

· Grade 304 – Offers excellent corrosion resistance and is suitable for general-purpose applications.

· Grade 316 – Contains molybdenum, enhancing strength and resistance to harsh environments, making it ideal for heavy-load structures.

Thicker walls provide greater rigidity and load-bearing capacity. A stainless square tube with a thicker gauge can handle higher weights without bending or buckling.

Larger cross-sectional sizes distribute weight more effectively, increasing structural stability. For heavy-duty applications, a wider stainless square tube is recommended.

The distance between support points significantly impacts load capacity:

· Shorter spans = Higher load capacity

· Longer spans = Reduced maximum weight support

Exposure to extreme temperatures, moisture, or corrosive chemicals can weaken the tube over time. Grade 316 stainless square tubes are best for outdoor or industrial environments.

Thanks to its strength and aesthetic appeal, stainless square tube is widely used in:

· Support beams – Provides structural integrity for buildings and bridges.

· Handrails & guardrails – Combines safety with a sleek, modern look.

· Framing systems – Used in glass facades and modular structures.

· Tables & chairs – Ensures durability while maintaining a stylish appearance.

· Shelving & racks – Supports heavy loads in commercial and industrial storage.

· Conveyor systems – Handles high weights in manufacturing plants.

· Equipment frames – Provides stability for heavy machinery.

Engineers use specific formulas to determine the maximum load a stainless square tube can support. Key factors include:

· Moment of Inertia (I) – Measures the tube’s resistance to bending.

· Modulus of Elasticity (E) – Indicates how much the material will deform under stress.

· Safety Factor – Ensures the tube can handle more than the expected load to prevent failure.

For precise calculations, consult engineering handbooks or use structural analysis software.

For optimal performance, prioritize Grade 316 stainless square tubes in corrosive or heavy-load applications, while Grade 304 suits general-purpose uses with moderate demands. Always match wall thickness and dimensions to your project's load requirements, remembering that thicker walls and shorter spans significantly enhance structural integrity.

Whether for construction, industrial, or design applications, proper stainless square tube selection ensures both safety and longevity. Consult with suppliers to verify specifications and get expert recommendations tailored to your project's unique demands. For premium materials and technical support, reach out to trusted stainless steel specialists today.