News

Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

Water treatment plants require durable, efficient, and corrosion-resistant filtration solutions to ensure clean and safe water output. Among the most critical components in these systems are stainless steel screen pipes, which play a vital role in removing sediments, debris, and contaminants.

This article explores why stainless steel screen pipes are indispensable in water treatment facilities, their key benefits, and how they outperform alternative materials.

Stainless steel screen pipes are perforated or wire mesh tubes made from high-grade stainless steel (typically 304 or 316). They are designed to filter out particles while allowing water to pass through efficiently.

· Slotted Screen Pipes – Precision-cut slots for fine filtration.

· Wire-Wrapped Screens – Welded mesh for high flow rates.

· Perforated Screen Pipes – Laser-cut holes for coarse filtration.

· Unlike carbon steel or plastic screens, stainless steel screen pipes resist rust, scaling, and chemical degradation from chlorine, ozone, and other water treatment chemicals.

· 316 stainless steel is ideal for saline or high-chlorine environments.

· Withstands high-pressure backwashing and mechanical stress.

· Long service life (20+ years with proper maintenance).

· Customizable slot sizes (0.1mm–5mm) for different filtration needs.

· Prevents clogging with smooth internal surfaces.

· Non-porous surface prevents bacterial buildup.

· Compatible with CIP (Clean-in-Place) systems for automated cleaning.

· 100% recyclable, reducing environmental impact.

· Lower replacement frequency than plastic screens.

Stainless steel screen pipes are used in multiple stages of water purification:

· Removes large debris (leaves, algae, plastics) from raw water sources.

· Filters out sand, silt, and suspended solids in multimedia filters.

· Acts as a pre-filter to protect delicate reverse osmosis (RO) membranes.

· Screens out solids in sludge dewatering and effluent filtration.

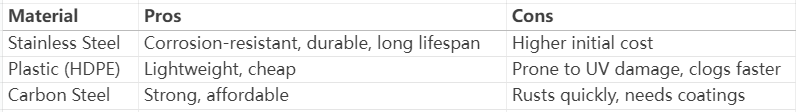

Conclusion: While plastic and carbon steel are cheaper, stainless steel screen pipes offer superior longevity and performance in demanding water treatment environments.

When selecting stainless steel screen pipes, consider:

· Material Grade (304 for freshwater, 316 for brackish/chlorinated water)

· Slot Size (smaller slots for finer filtration)

· Diameter & Length (matches system flow rates)

· End Connections (threaded, flanged, or welded for easy installation)

· Regular Backwashing to prevent clogging.

· Inspect for Scaling (acid cleaning if mineral deposits form).

· Check for Physical Damage (dents, mesh wear).

Stainless steel screen pipes are a critical investment for water treatment plants, offering unmatched durability, filtration efficiency, and resistance to harsh conditions. Whether for municipal drinking water or industrial wastewater treatment, they ensure reliable performance with minimal maintenance.

Looking for high-quality stainless steel screen pipes? Contact us today for customized solutions tailored to your filtration needs!