News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Selecting the correct stainless steel tubing wall thickness is crucial for ensuring durability, performance, and cost-efficiency in various industrial and commercial applications. Whether you're working with hydraulic systems, medical devices, or construction projects, understanding how to choose the right stainless steel tubing wall thickness can prevent failures, reduce costs, and optimize performance.

In this guide, we’ll explore the key factors that influence stainless steel tubing wall thickness selection, common industry standards, and practical tips to help you make the best decision.

The internal or external pressure a tube must withstand directly impacts the required wall thickness. Thicker walls provide higher burst pressure resistance, making them ideal for:

· Hydraulic and pneumatic systems

· High-pressure gas or liquid transport

· Structural applications with heavy loads

While stainless steel is naturally corrosion-resistant, thinner walls may degrade faster in harsh environments (e.g., marine or chemical industries). A slightly thicker wall can extend service life.

Thicker walls increase material costs and weight, which may not be necessary for low-pressure applications. Balancing strength with budget is essential.

Different industries follow specific standards for stainless steel tubing wall thickness, such as:

· ASTM A269 (general-purpose tubing)

· ASTM A213 (heat exchanger tubes)

· ISO 1127 (dimensions for precision tubing)

· Pressure rating? (Higher pressure = thicker walls)

· Environmental exposure? (Corrosive settings may need extra thickness)

· Regulatory compliance? (Medical, aerospace, and food-grade industries have strict standards)

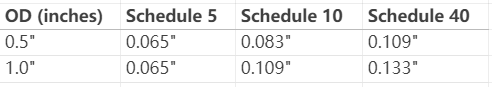

Manufacturers provide stainless steel tubing wall thickness charts based on outer diameter (OD) and schedule (e.g., SCH 10, SCH 40). For example:

If unsure, conduct pressure tests or consult an engineer to ensure the selected stainless steel tubing wall thickness meets safety and performance needs.

· Choosing too thin walls → Risk of leaks or ruptures under pressure

· Over-specifying thickness → Unnecessary material costs and weight

· Ignoring industry standards → Non-compliance leading to project delays

Selecting the right stainless steel tubing wall thickness requires balancing strength, cost, and application needs. By understanding pressure requirements, environmental factors, and industry standards, you can make an informed decision that ensures longevity and efficiency.

For expert advice on stainless steel tubing wall thickness, contact us for tailored solutions.