News

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Passion, dedication, innovation, enterprising, integrity, truth-seeking, altruism, win-win

Among modern corrosion-resistant alloys, Duplex SS 2205 UNS S31803 stands out as one of the most widely used duplex stainless steels. It offers a remarkable balance of strength, corrosion resistance, and cost-effectiveness, making it a preferred material in industries such as oil and gas, chemical processing, desalination, and marine engineering. This article explores the composition, microstructure, and mechanical properties of duplex stainless steel 2205 in detail.

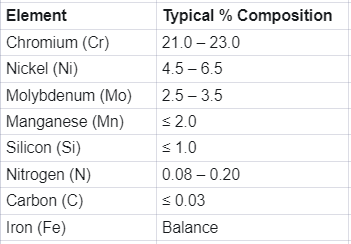

Duplex SS 2205 (UNS S31803) is a nitrogen-enhanced stainless steel containing approximately equal proportions of austenite and ferrite phases. Its chemical composition ensures both high strength and excellent resistance to various forms of corrosion.

The combination of chromium, molybdenum, and nitrogen gives duplex ss 2205 uns s31803 a high Pitting Resistance Equivalent Number (PREN)—typically above 35—making it far more resistant to chloride-induced corrosion than 316L stainless steel.

The microstructure of Duplex SS 2205 UNS S31803 is a dual-phase structure consisting of approximately 50% austenite and 50% ferrite after proper solution annealing (usually around 1050°C followed by rapid cooling).

· Ferrite phase (α): Provides high yield strength and resistance to stress corrosion cracking.

· Austenite phase (γ): Contributes to toughness, ductility, and improved corrosion resistance.

Maintaining a balanced microstructure is critical. Excessive heat input during welding or improper heat treatment can lead to the formation of harmful intermetallic phases such as sigma (σ) or chi (χ), which can drastically reduce toughness and corrosion resistance.

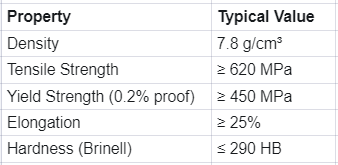

The dual-phase nature of duplex ss 2205 uns s31803 gives it mechanical properties superior to those of conventional austenitic grades like 304L or 316L.

These values demonstrate that Duplex 2205 offers roughly twice the yield strength of 316L stainless steel, allowing for lighter constructions and reduced material costs without compromising safety or durability.

Duplex 2205 stainless steel exhibits outstanding resistance to:

· Pitting and crevice corrosion in chloride environments

· Stress corrosion cracking (SCC) due to its ferritic content

· Uniform corrosion in acidic and alkaline conditions

Because of these properties, Duplex SS 2205 UNS S31803 is often used in desalination plants, offshore platforms, heat exchangers, and pressure vessels where chloride exposure is a major concern.

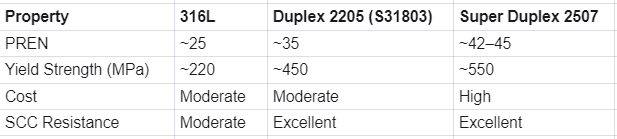

Duplex 2205 provides an ideal middle ground between austenitic and super duplex stainless steels, balancing performance and cost.

Thanks to its excellent combination of strength and corrosion resistance, duplex ss 2205 uns s31803 is commonly used in:

· Offshore oil and gas pipelines

· Heat exchangers and pressure vessels

· Chemical and petrochemical processing equipment

· Pulp and paper industry components

· Marine environments and desalination systems

Duplex 2205 is typically solution-annealed at 1020–1100°C followed by rapid cooling to maintain the correct phase balance. During fabrication, careful control of heat input is essential to prevent the formation of intermetallic phases. Welding should use filler metals such as ER2209 to match corrosion resistance and mechanical properties.

Duplex SS 2205 UNS S31803 combines high mechanical strength, superior corrosion resistance, and good weldability—making it one of the most versatile stainless steels in modern engineering. Its balanced microstructure and alloy design allow it to outperform traditional austenitic grades while remaining cost-effective. For industries requiring reliability in harsh environments, Duplex 2205 remains a proven and trusted choice.